Story 11: Integrating production with management – how asphericon moved into its new headquarters

Relocation, even within the same city, is a major logistical challenge accompanied by the prospect of guaranteed chaos. In a nutshell, it’s a stressful business. No matter how well you plan, something’s bound to get broken, lost, or simply go wrong. To give you an idea of the sheer scale of this challenge, just think of your previous moves, and then add machines worth millions and each weighing more than a tonne!

Fig. 1: Field of visions – the building site for the current company headquarters back in 2010

Anyway, let’s go back to 2011 when asphericon’s first company building, including the production facility, was ready to occupy. Investment totalling about €5 million coupled with plenty of new ideas had gone into the new location on the JenA4 industrial estate in Jena. The previous rented premises in Jena Technology and Innovation Park had become too cramped for our burgeoning company, and the new production space over 1,600 square metres in size seemed ideal to step up our manufacturing capability. Naturally, everyone at asphericon was looking forward to its new headquarters, where research, development and production were finally going to be concentrated at a single location. The adjoining office complex with total floorspace of some 600 square metres meant that production and administration were no longer separated and allowed the employees to be more closely involved in all internal processes. In addition, another factor promoting this integration was the basic structure of the modern architecture. Designed for communication, it enabled all colleagues to share ideas and boost their participation.

Fig. 2: Ceremonially breaking ground in early 2011. Among those joining CEOs Sven Kiontke and Alexander Zschäbitz were Albrecht Schröter, then the Mayor of Jena (third from left), and Wilfried Röpke, Managing Director of Jena’s business development agency (second from right)

Another important aspect of the new building was its emphasis on smart, environmentally friendly construction, especially the rooftop photovoltaic systems and the use of waste process heat to keep the premises warm. asphericon still benefits from the ecologically sustainable planning of its company headquarters, supplementing it in recent years to include various electromobility services. For example, back in 2016, one of the first charging stations in Jena was installed outside the building to keep the company’s new fleet of electric vehicles on the road.

Fig. 3: A view of the roof. Since 2014, asphericon has had is own photovoltaic system generating power, including for its own electric vehicles

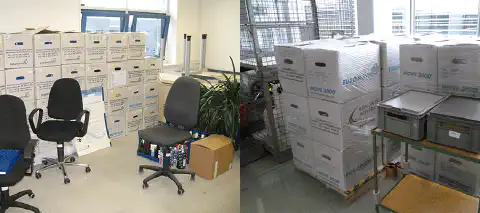

Building work proceeded swiftly, and the new headquarters was completed in October 2011 after less than a year. It was now time for the logistical feat to begin, requiring umpteen deliveries to the new premises. Well aware that production had to be restarted soon to ensure customers’ orders weren’t disrupted, we allowed ourselves just a week for the move. This ambitious schedule meant everyone had to pitch in. Apart from the countless boxes, new, efficient production lines also had to be installed. What’s more, the machines from the previous production plant – all real heavyweights! – had to be moved to the new site and installed as well.

Fig. 4: With everything safely back, asphericon was ready for a new, important chapter in its history

asphericon already had plenty of experience moving machinery weighing several tonnes. A few years earlier, the delivery of a new, very expensive machine had caused something of an uproar. A forklift truck had been obtained to transport it from the lorry to the production area. However, it rained heavily the night before, and so the paths and roads were wet and slippery. On the big day, the truck bearing the long-awaited machine turned into the driveway and unloading could begin – or at least, that was the idea. In fact, instead of lifting the machine, the reverse happened. The forklift truck reared up dangerously – evidently, the machine was stronger! asphericon’s production manager hung onto the forklift for dear life and tried to drag it back down to the ground, but to no avail. The problem was only solved by a forklift truck with a lifting capacity of five tonnes. “We can laugh about it now, but at the time it was a nightmare!” recalls CEO Alexander Zschäbitz. By the way, it’s worth mentioning that the production manager who showed such dedication later became the company’s health and safety officer! ;)

Fig. 5: Delivering heavy machinery by forklift – this time it all went smoothly!

We all learn from our mistakes. Everything went without a hitch during the big move in 2011, and the new building was officially opened to great fanfare in November. Since then, asphericon has grown continuously, and just five years later it was time to consider increasing the production area from 2,300 to 5,000 square metres. asphericon has successfully developed from a start-up into an established technology leader. Over the years, the company has grown from 50 members of staff in 2011 to a powerful team of over 170 employees at our three locations worldwide. Even so, the ‘old hands’ still remember the story of the forklift truck being dragged up into the air with a smile! Now that the team has mastered this and other milestones, there’s nothing to stop us opening another production plant, is there?

To find out more, you’ll just have to wait until the next story!