News

News from the world of asphericon

May 27, 2025

System solutions, ultrafast laser innovations and hands-on workshops

asphericon presents system solutions, new products and hands-on learning opportunities at Laser World of Photonics 2025

May 15, 2025

Master Laser Light - From Beam Shaping to Ultrafast Optics

After a two-year break, the asphericon ACADEMY returns to the Laser World of Photonics in Munich.

Nov 28, 2024

Innovative VR Technology

The VR-based training tool from asphericon, developed in cooperation with Centre for Digital Transformation Thuringia and Consensive, wins the Digital Award Thuringia 2024 in the Users of Digital Technologies category.

Oct 17, 2024

asphericon appoints key positions in sales and focuses on global expansion

asphericon announces strategic expansion of global sales activities. Sebastian Henkel has been appointed Vice President Global Sales & Procurement, “BeamTuning” brand will be strengthened by new personnel structures to address global market in targeted manner.

Oct 9, 2024

City Cycling 2024 - The results

Jena’s CITY CYCLING campaign has once again achieved impressive achievements and set new records. With over 4,000 participants in 161 teams, the campaign was a complete success.

Jul 16, 2024

STADTRADELN 2024

From 30.08.-19.09.2024, it’s time to pedal hard again in Jena. CITY CYCLING calls to switch from car to bike as often as possible and collect kilometers.

Jun 12, 2024

Innovation in optics and aerospace

asphericon debuts at ILA Berlin 2024 with cutting-edge optical solutions for the aerospace industry

Dec 13, 2023

Facade award for sustainable timber hybrid building

asphericon has been awarded the Jena Facade Prize 2023 for its investment in a new, sustainable timber-hybrid building.

Nov 30, 2023

Ernst Abbe Prize for Innovative Entrepreneurship for Sven Kiontke

CEO of asphericon GmbH was awarded the Ernst Abbe Prize for innovative entrepreneurship.

Nov 13, 2023

Jena 2023 Digital Summit

As part of the Digital Summit in Jena, three innovative companies will be presenting themselves in a top-class panel discussion on Nov 20 & 21. Among them asphericon.

Nov 6, 2023

New distribution partnership in Israel

asphericon and ROSH Electroptics LTD, a leading distributor of optical and optomechanical components, are entering into a strategic partnership starting November 2023.

Nov 3, 2023

Successful City Cycling in Jena

Germany-wide community initiative to promote sustainable mobility and reduce CO2 emissions is coming to an end with impressive results in Jena.

Apr 27, 2023

Designing tomorrow’s systems today

asphericon ACADEMY returns to the Laser World of Photonics

Apr 5, 2023

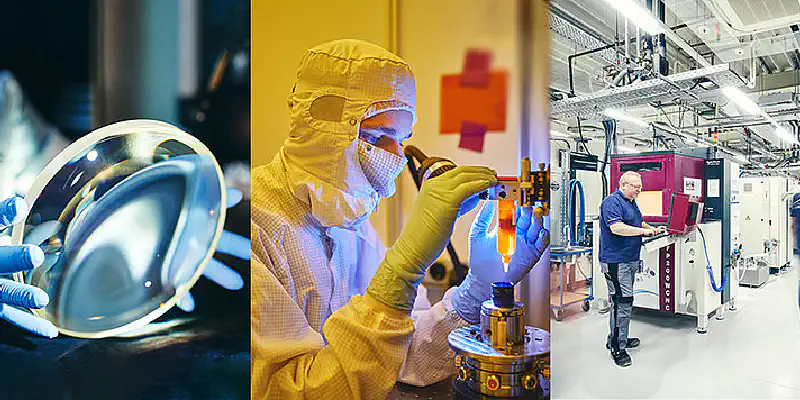

Excellence redefined

TÜV Thüringen endorses outstanding quality in aspherical systems production

Oct 19, 2022

Dr. Ulrike Fuchs elected to the Board of Directors of OPTICA

Dr. Ulrike Fuchs elected to the Board of Directors of OPTICA

Oct 11, 2022

Topping-Out Ceremony for Sustainable new Building

Topping-Out Ceremony for Sustainable new Building for the first wood-hybrid construction in the photonics industry

May 30, 2022

asphericon backing triathlete Maja Betz

asphericon is pleased to announce that it’s now supporting triathlete Maja Betz

Apr 21, 2022

Squaring the circle

asphericon to unveil new beam shaper at Laser World of Photonics 2022

Mar 21, 2022

asphericon expands its headquarters

More room for product development and administration

Feb 8, 2022

New head of asphericon purchasing department

Technology leader affiliates purchasing department with sales department headed by Sebastian Henkel

Speak to our team

Always the latest news from asphericon