Spherical mirrors

Precise concave and convex mirrors from asphericon

Concave and convex spherical mirrors

At asphericon, we offer precision-crafted concave and convex spherical mirrors customized to your unique needs. Production spans a wide array of materials, including various types of glass, crystals (e.g. silicon) and metals. Utilizing state-of-the-art coating technologies, we also provide a wide range of high-end coatings from the visible (VIS) to the infrared (IR) range.

Benefits

- Customized mirrors

- Materials: optical glass, quartz glass, metal

- High-quality custom coatings (spectral range from 190 nm to 5.1 µm)

- Reasonable delivery times

- RoHS-compliant production

Spherical mirror specifications

| Spherical Mirrors | |

|---|---|

| Diameter | up to 420 mm |

| Diameter Tolerance | +0/-0.3 mm |

| RMS irregularities (RMSi) | 25 nm |

| Surface imperfections (Scratch/Dig) | 20 - 10 |

| Coating | Customer specific (e.g. dielectric coatings, metal-based coatings, filter coatings) |

| Measurement | Full-surface interferometric |

| Material | Customer specific (almost any type of glass, fused silica, germanium, silicon, ZERODUR®) |

| Mounting | Customer specific |

Spherical mirrors portfolio

Compared to parabolic mirrors, spherical mirrors have a simpler structure, making their production much simpler. However, since the focal point of a spherical mirror suffers from spherical aberration and doesn’t concentrate light rays into a single point, choosing the right mirror must always be application-specific.

Concave spherical mirrors from asphericon

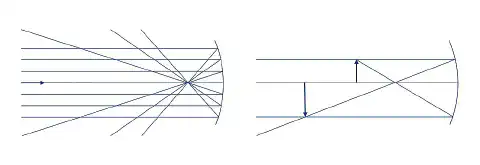

Used in fields like medicine and the production of car headlights and other lights, concave spherical mirrors’ focal length is determined by the formula f = 2/r, where r represents the radius of curvature. These mirrors can focus parallel light to a focal point and, conversely, reflect light from the focal point in nearly parallel beams. In car headlights, for example, light from the bulb is captured and efficiently reflected forward (see Fig. 1).

Figure 1: Working principle (left) and diagram (right) of a concave mirror. Its inwardly curved reflecting surface has a collecting effect, concentrating light rays parallel to the optical axis into a single point.

Concave spherical mirrors are also employed in telescopes, such as in spectrometers for earth observation. With the correct coating or when made from metal, they can be used to pick up TV, radio and radar waves.

aspericon’s convex spherical mirrors

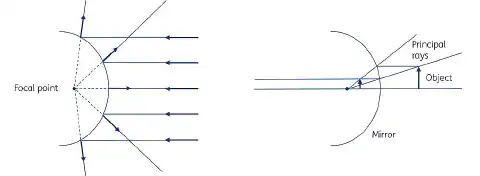

Convex mirrors, also known as diverging mirrors, have reflecting surfaces that curve outwards. Since they disperse light outward, they can’t be used to focus light. They produce a virtual image, with both the focal point and the centre of curvature as imaginary points within the mirror that can’t be accessed. As a result, images produced by convex mirrors can’t be projected onto a screen because the image is located inside the mirror. Though smaller than the reflected object, the image grows larger as the object nears the mirror. More importantly, convex spherical mirrors provide wider fields of view compared to other reflective surfaces like flat or concave mirrors. This ability to consolidate surrounding light into a single image is used in applications such as rear-view mirrors in cars and security surveillance .

Figure 2: Working principle (left) and diagram (right) of a convex mirror. The reflecting surface is curved outward, which makes it scattering.

Your request