VIS Coatings

Coating solutions for applications with visible light

Coatings for the visible range, from high-power lasers to entertainment media

The spectrum that the human eye can perceive ranges from 380 nm to 750 nm and is referred to as the visible spectrum (VIS). Possible applications range from the generation of projections, to spectrometers that analyze large areas of light, to the industrial processing of various materials.

Industrial use and projections

All types of projection, from laser pointers to position-indicating lasers in manufacturing and projectors, have one thing in common: they require lower power relative to other applications. Preference is therefore usually given to cost-effective solutions in this area. This requirement is met by diode lasers, for example. They generate all relevant wavelengths of the VIS spectrum and have relatively low acquisition and maintenance costs.

Significantly higher powers are necessary for manufacturing processes, especially in interaction with metals. Drilling and cutting of thicker plates or materials that absorb the usual wavelengths more poorly, such as gold or copper, can be achieved by high powers in the kW range. Higher demands on optical components come into play when short pulsed lasers are used. Although in such cases the average power is lower, a single pulse is highly energetic if the power is transmitted in picoseconds. Alternatively, very good results can be achieved with specialized wavelengths, in this case green lasers at 515 nm, among others. More about laser applications can be found on our application pages. If a fixed wavelength is used, coatings such as so-called V-Coatings are one way to achieve better results. These coatings have a very high transmission at the intended wavelengths. Learn more about filter and anti-reflection coatings on our blog.

Optical analyses in the VIS spectrum

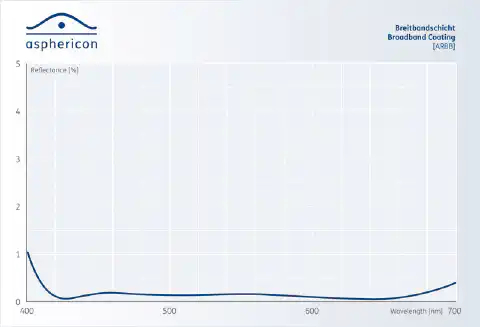

In addition to industrial use, optics designed for VIS are often used for spectrometers. Here, for example, a distant star in space, a sample on a microscope or an agricultural field is analyzed over a broad spectrum of wavelengths. For this purpose, the optics are usually coated with a reflection-minimizing broadband (ARBB) coating (see Figure 1). Such coatings exhibit very low reflectance for a wide range of wavelengths. Reflectors for the visible spectrum are often treated with either dielectric coatings or metallic silver coatings, as these have very good properties for the visible range.

Figure 1: Example of a broadband coating for antireflection

For laser applications with wavelengths outside the visible spectrum, it is necessary to provide protective measures for all persons present during an application to prevent damage to the eyes. However, some lasers in the VIS spectrum also emit part of their radiation in other spectral ranges and can thus also endanger users, since any reflected beams are not noticed. For protection, protective goggles can be used, but also optical filter coatings, which absorb e.g. IR rays.

Optical coatings in the VIS range from asphericon

- Wavelength range: 380 - 750 nm

- Coating: e.g. A-Coating (400 - 600 nm), D-Coating (350 - 700 nm), L-Coating (532 nm), Y-Coating (320 - 450 nm), filter coatings

- Materials: glass, fused silica, crystals

- Substrate sizes: up to 350 mm diameter

- Processes: Electron Beam evaporation, Ion Beam Assisted Deposition, Magnetron Sputtering

Curves with specific information about the respective coating can be found on the service page for optical coating and in the download area.