Optical Quality Control

Lenses and sensors for quality assurance

Lenses and sensors for quality assurance

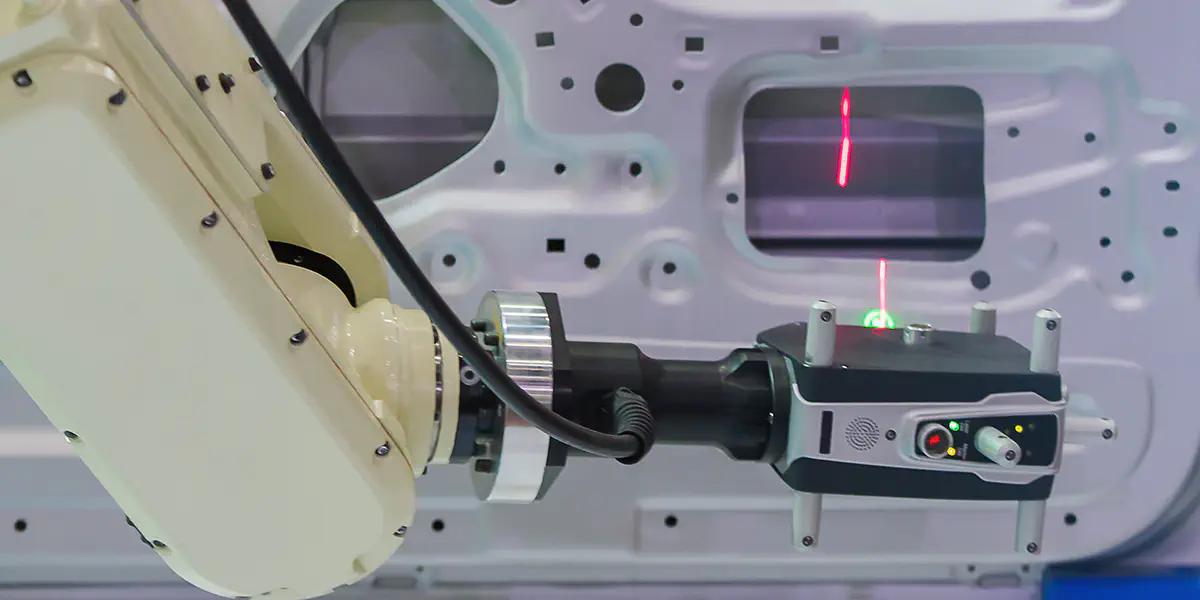

Optical quality control refers to a wide variety of test methods for determining and ensuring the quality of production products. This allows the quantity of components to be determined, as well as their dimensions, the quality of lasered inscriptions or surface properties. Since the inspection takes place optically, i.e. without contact, there is no risk of damaging surfaces. Common methods for optical quality control are e.g.:

- Laser Scanning,

- Imaging or

- Thermography Systems.

Interferometry is a special optical measuring method, which is mainly used in the optical industry. To control the properties of spherical and aspherical surfaces, the principle of interference fringes, which are produced by the superposition of coherent light waves, is applied.

Advantages of optical quality control

Objects to be inspected are recorded holistically within the selected procedure and the existing values, such as dimensions or temperature, are compared with the required target values. Each production step can be monitored permanently and in real time during the running production process, enabling rapid intervention in the event of faulty products. Optical quality assurance also prevents pseudo rejects. Costs can thus be reduced, and time can be used effectively. The result: maximum economic efficiency. Applications for optical quality control can be found, for example, in the automotive industry, medical technology or mechanical engineering, but also in optics/photonics.

High-end optics, sensors and infrared cameras as the basis for visual quality controls

Laser scanning/Imaging

State-of-the-art optics and sensors form the basis of every optical quality control. Laser-based camera systems and optical sensors can, for example, scan contours to sort out faulty products. The high accuracy of optical quality controls permits reliable quality testing even for complex components. Increasingly tighter tolerances and the inspection of surface properties can be achieved precisely and reproducibly. High-precision optics, such as perfectly imaging aspheres, make it possible to fully record the workpieces and products to be inspected. Laser beams can be ideally bundled or expanded; camera lenses can be refined for daily use.

Thermography

During thermal quality control via infrared cameras of a thermography system, the infrared rays emanating from the workpiece are visualized. The temperature measurement of the workpiece reveals possible incorrect tempering, which could lead to reduced quality in the following production steps, for example deviations from the nominal geometry. High-quality infrared optics are used for a targeted detection of heat radiation, for a safe and reliable quality determination.

Interferometry

Interferometers can be used to measure very sensitive optical surfaces. The superposition of a reference beam with the beam reflected from the surface to be measured produces so-called interferograms. These represent a full-surface error map of the measuring object and allow conclusions to be drawn about the quality or further processing of an optical system. High-resolution lenses are at the heart of interferometric measurements.

(IR) aspheres from asphericon provide the best imaging properties and can be used in various optical test methods. We would be pleased to advise you on the use of these and other optics from our product portfolio. You have an interferometer in your own machine park and are looking for a powerful lens? Also discover our portfolio of individual optical systems.