Freeform Optics

High-performance, compact and lightweight

The experts in freeform optics

Freeform optical lenses with no rotational symmetry enable totally new concepts for optical systems. Freeform optics allow fewer elements to be used for optical systems, making them smaller, lighter and more efficient. And when it comes to freeform optics with maximum precision – all the way from design to batch and series production – asphericon is the expert.

Discover the many benefits of freeform optics and systems made using asphericon’s innovative technology.

- Unconventional shapes with all sorts of materials (including ceramics and infrared materials)

- Lenses, mirrors and monolithic elements with diameters up to 300 mm

- Multi-focal, compact systems

- Exceptional surface quality (RMSi > 50 nm)

- CGH-free measurement including all position tolerances (complete component)

- Individual coating and mounting concepts

- Optical design consulting for production-optimized system designs

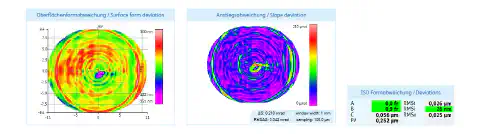

Figure 1: Example measurement of a freeform optic made by asphericon using grinding and polishing. The graphic shows the wavefront map with associated measured surfaces and part tolerances after two correction polishes (performance target: RMS WFE < 35 mλ).

Specifications

| Standard Quality | Precision Quality | Diamond-Turning | ||

|---|---|---|---|---|

| Diameter | 8 – 300 mm | 4 – 300 mm | 1 - 150 mm | |

| Diameter Tolerance | ± 0,1 mm | ± 0,01 mm | ||

| Center Thickness | 2 - 60 mm | 2 - 60 mm | ab 0,5 mm | |

| Center Thickness Tolerance | ± 0,1 mm | ± 0,05 mm | ||

| RMS Irregularities (RMSi) | 0.75 – 0.3 µm | 0.09 µm | 0.1 µm | |

| Surface Roughness | 2.0 – 3.0 nm | 1.5 – 2.0 nm | bis zu 1 nm | |

| Full-surface Interferometric Measurement | optional | optional | optional | |

| Coating | customer-specific | customer-specific | customer-specific | |

| Materials | customer-specific (including ceramics) | customer-specific (including ceramics) | customer-specific (including ceramics) | |

| Mounting | customer-specific | customer-specific | customer-specific |

From vision to batch

asphericon has been working on the (batch) production of freeforms for many years. Together with powerful partners from the region, the development and marketing of innovative freeform optical systems were decisively advanced within the “Freeform Optics Plus (ƒo+)” regional growth core. In 2018, this internationally acclaimed project received the Collaborative Research science award for pioneering approaches to the production of freeforms from the Donors’ Association for the Promotion of Sciences and Humanities in Germany.

In recent years, asphericon has introduced new manufacturing strategies and honed measuring concepts in several projects, amassing a wealth of expertise in freeform optics and systems.

At Laser World of Photonics 2022, a reflective beam shaper based on freeform optics was unveiled by asphericon. The freeform surfaces compensate for asymmetries and reduce the volume by half. The new beam shaper makes the laser a flexible tool suitable for both high laser powers up to 10 kW and a wide range of wavelengths.

Alvarez System

Discover also our freeform systems based on Alvarez lenses. Such systems are particularly convincing due to their compact freeform optical design. Thanks to the surface shape it is possible to vary an optical function infinitely. Examples are the dynamic change of the focal length of a system, the compensation of divergence of laser beams, as well as the creation of square Top-Hat profiles. We will be happy to answer your questions about our Alvarez lenses in personal contact.

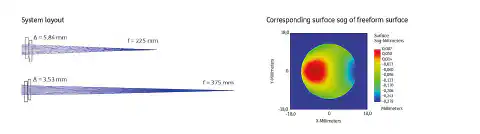

Figure 2: Dynamic change in the focal length of a system through the use of Alvarez lenses.

Specification of freeform surfaces

Freeform optics are refractive and reflective surfaces that differ significantly from spherical and aspheric geometries. Freeform optics manufacturing begins with the definition of the surface. In addition to a clear description of the optics, an equation, point cloud or 3D model is required for production.

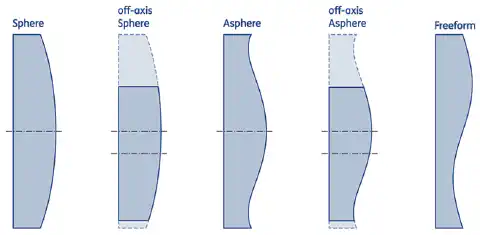

One possible kind of freeform optics is the decentered use of an actually rotationally symmetrical lens, which is thereby adapted to the off-axis range. The optically relevant part is cut out (see Fig. 3), also to save space in systems. In terms of production, a symmetrical lens is thus cheaper and easier to manufacture. Regarding the optical design, its surface is already a freeform due to the optical effect achieved. However, a side effect of such a decentered lens is the increase of aberrations with oblique incident light, which ultimately leads to a rapid reduction in image quality. The great advantage of “real” freeforms is, they enable a very good imaging quality thanks to their special geometry and high number of degrees of freedom. However, the demands on the optical design and manufacturing process are much more complex and demanding compared to conventional symmetrical lenses.

Figure 3: Evolution of different lens shapes from sphere to freeform (increase in complexity from left to right)

Advantages and challenges of freeform optics

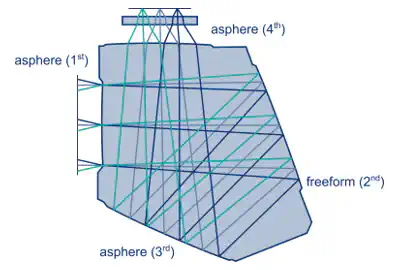

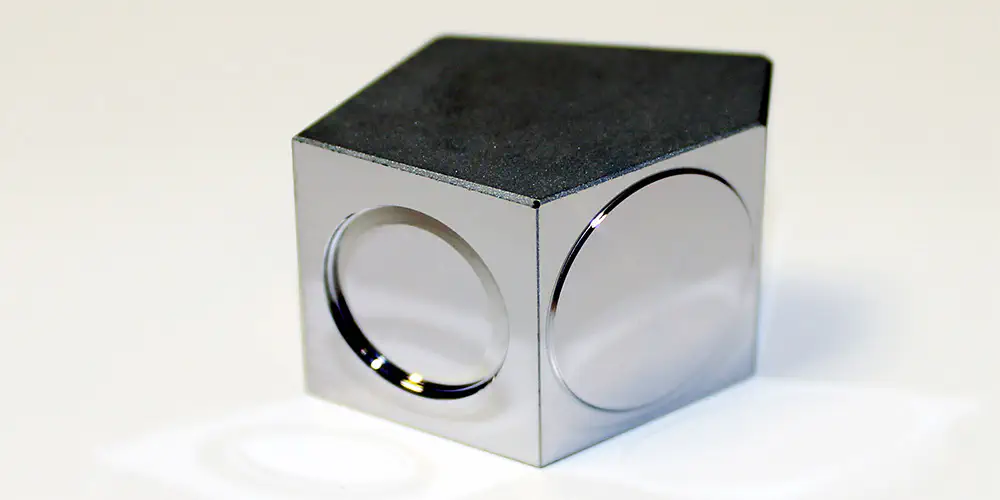

Based on their special surface shape, freeform optics can provide functions that cannot be achieved with classic optics. Especially in optical systems that require a folding of the beam path, e.g. monoliths, freeform optical lenses are extremely advantageous and can replace existing, larger arrangements such as mirror systems. To illustrate this, the following figure shows the optical design of a monolithic system consisting of three aspheric and one freeform surface with simulated beam path folding. The shown monolith was created within the research and development platform fo+.

Figure 4: Optical design of a monolithic system.

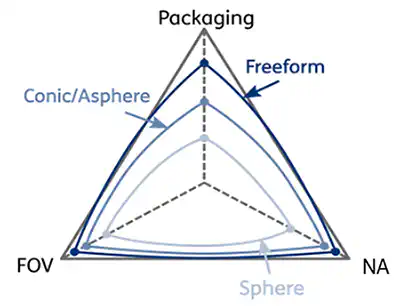

Compared to spheres and aspheres, improvements in field of view (FOV) and numerical aperture (NA) as well as in size and weight can be achieved using freeforms (see Fig. 5). However, a high quality of the freeform optics is an absolute prerequisite for a constant high quality of the optical system.

Figure 5: Comparison between sphere, asphere and freeform optics in terms of field of view (FOV), numerical aperture (NA) and size.

The advantages of freeform optics mainly are

- their compact shape,

- the potential reduction in size of optical systems, and

- the enabling of new optical functions.

Due to their optical shapes/surfaces, which have few or no symmetry, freeform optics have many degrees of freedom. Their manufacturing is similar to that of highly complex aspheres. The surface shape and local changes in inclination influence the complexity of the geometry, the manufacturing process and the measurement. Thanks to modern manufacturing and measuring equipment, asphericon also produces unconventional freeforms and systems. Furthermore, we offer optical design consulting, optical coating, mounting and CGH-free measurement (complete component, including all position tolerances).

Reference project

Your request