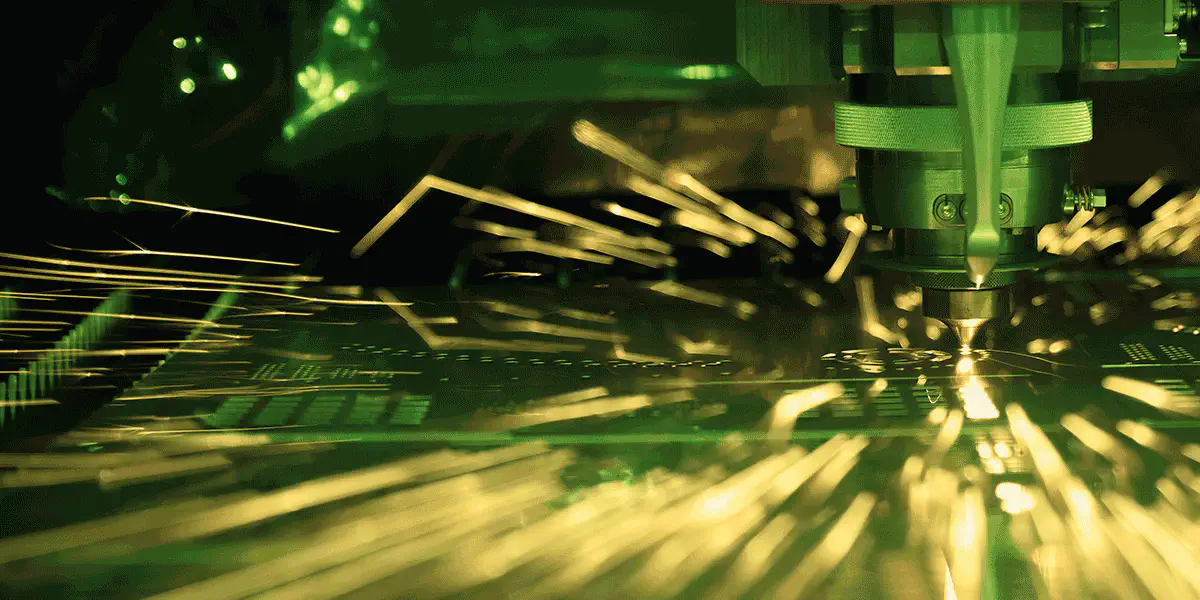

Wafer Cutting

A laser-based cutting process for processing fragile crystalline blanks

Wafer cutting is a very effective and material-friendly process for separating individual wafer components. Wafers are square or circular thin discs which are obtained from mono or polycrystalline blanks and serve as a base plate for electrical components such as microchips. Due to the complex manufacturing process and the fragile shape of the wafer plates, laser cutting is an effective separation process.

Advantages of laser wafer cutting

When cutting wafers, it is important to keep the loss of the material to be processed as low as possible and at the same time to protect the material in the best possible way. If these two requirements are met, work can be carried out economically and the cutting yield is correspondingly high. Compared to mechanical wafer cutting processes such as sawing, the laser-assisted process minimizes microcracks at the cutting edges. In addition, laser-guided wafer cutting convinces with a narrower cutting width, whereby more surface area of the price-intensive wafer can be used while protecting the material at the same time. Furthermore, there is no tool wear, as the laser-based wafer cutting is contact-free. The risk of wafer breakage during the cutting process can thus be virtually eliminated.

Advantages of laser cutting

- Gentle and precise processing of materials

- Clean cut edges

- Flexible guidance over the element to be machined

- High reproducibility

Cylinder and beamshaper for effective material processing

For effective and clean laser guidance, high-quality optics are necessary, such as acylinders. Aspherical cylinders are characterized by a line in the focal point, i.e. there is not only one focal point in the focus. The result for wafer cutting is a fast and time-saving cutting process that delivers superior results. Lowest roughness values of the acylindrical surface lead to a perfectly focused line and guarantee best imaging results. asphericon’s production is rounded off by high-quality finishing layers from UV to the near infrared range.

Talk to us about customized aspherical cylinders for your wafer production or inform yourself about our BeamTuning product range and the components for shaping perfectly focused laser beams and thus optimal cutting edges.