Technologies

For Highest Quality and Accuracy

asphericon Technologies

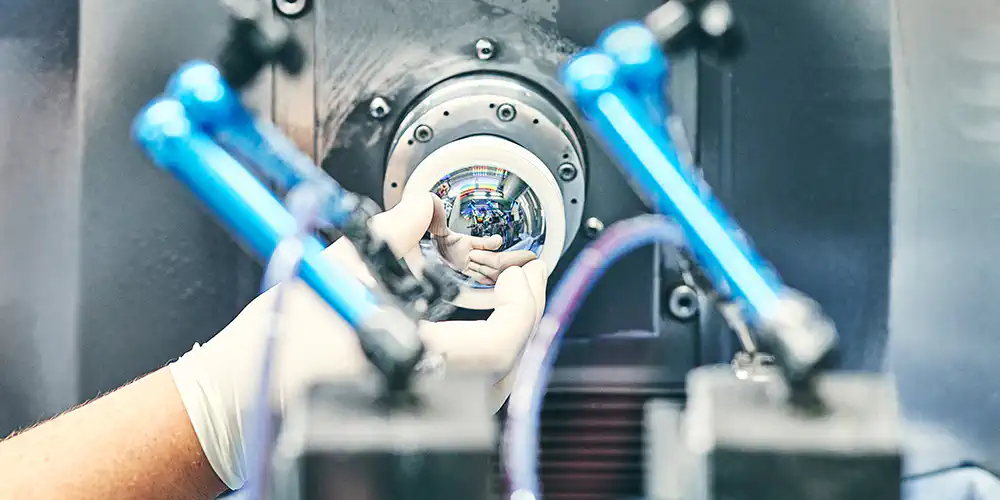

Driven by the idea of developing new technologies and optimizing existing ones, we continuously work on advancing and improving our processes. Whether it’s CNC machining, diamond turning, or high-end finishing, asphericon strives for ever-improving quality and higher accuracy - without ever losing sight of our customers’ economic interests. The globally unique and patented control software for CNC machining enables the production of small and large quantities with high precision. Ultra-precise diamond turning on almost any functional surface and modern polishing methods for minimal roughness values are achieved through this software. Coating technologies such as electron beam evaporation, ion beam-assisted deposition, and magnetron sputtering complement the portfolio.

CNC processing

Individual solutions at the highest level: Our patented technology to control CNC grinding and polishing machines with the ability to simulate processing methods, specifically developed by asphericon, forms the basis for our manufacturing.

Equipment:

- 10 production lines for CNC grinding and polishing

- Optotech polishing and grinding machines in ASM series for high precision grinding

- SPK, SPF and ASP-b for precise polishing

- ASP FFP-W for wheel polishing on the widest variety of lens materials

- Satisloh SPM series – efficient grinding

- Optical characterization of each asphere in the laboratory

DIAMOND TURNING

Diamond-turned optics in perfection: Ultra precise cutting by using monocrystalline diamond tools is the key technology for manufacturing virtually any optical functional surface with the utmost precision. This allows the processing of non-ferrous metals, nickel-phosphorus coatings, plastics, crystals and IR lenses.

Equipment:

- Moore Nanotech 250UPL ultra precise CNC diamond turning machine

- Moore Nanotech 350FG for ultra precise cutting using monocrystalline diamond

HIGH-END FINISHING

Precise for the highest demands: challenging optical applications demand ever greater surface form precision. asphericon delivers the required finish for your high-end products.

With asphericon ION-FinishTM and Magnetorheological Finishing-Technology® (MRF), it is now possible to process challenging aspheric optics in serial production for the first time. Thanks to this procedure, shape deviations are achieved that significantly exceed the current international standard. If every photon counts or high laser output is involved, scattered light should not be an issue thanks to the novel asphericon Ångström-Polishing, which enables roughness values of 5 Å (Rq according to ISO 10110) to be achieved on all aspheric surfaces.

📎 High-End Finishing Datasheet

Equipment:

- Ultra-precise ION-Scan 800 for waver-based coating thickness and frequency trimming

- QED Q-flex series – magnetorheological polishing of various materials

Learn more about our High-End Finishing Technologies on our blog.

Benefit from our expertise at every stage of value creation. We accompany you from the initial optics design through manufacturing and coating, precise measurement and documentation to the assembly of optic assemblies and their optical characterization.

COATING TECHNOLOGIES

asphericon’s optics manufacturing also includes various technologies for coating lenses and mirrors. The choice of optical coating depends on the properties of the material and the requirements of your optical systems. Our experts are happy to advise you on selecting the right technology for coating your application.

More detailed information about our coating technologies can be found on our blog.