UV Coatings

Optics for high power (laser) applications

Maximum energy thanks to ultraviolet optics and coatings for your application

Optical systems for ultraviolet wavelengths are usually provided with optical coatings. A distinction can be made between three basic functions:

- Reflection,

- Antireflection coating and

- Filtering of wavelengths.

In addition, coatings protect the surface of an optical system and ensure that it retains its optical quality even under harsh environmental conditions.

Special features of ultraviolet radiation for optics

Depending on the field of application, optical coatings for ultraviolet wavelengths are used to perform various tasks. For example, in material processing, the laser damage threshold and general stress on components is reduced. UV lasers are highly energetic and often emit short, intense pulses. Due to the low wavelength, even small impurities or lack of precision manufacturing are a challenge when using UV optics. Uniform optical coating with minimal tolerances is therefore essential for a high-quality product.

The shorter the wavelength or pulse duration, the higher the energy of the laser. This leads to the damage threshold, also called Laser Damage Threshold (LDT) or Laser Induced Damage Threshold (LIDT), of the optics based on ISO 21254 being more relevant. LDT or LIDT describes the maximum power on the optics at which statistically extrapolated no damage is to be expected. In active use, however, damage cannot be ruled out even if this limit is not exceeded. In the UV range in particular, severe wear is possible before a complete defect occurs. This represents a significant additional expense in the medical field. Modern coating processes and homogeneous surfaces minimize optical system failures and extend maintenance intervals.

Wavelengths and applications for UV optics

Ultraviolet radiation is shorter than the violet wavelength 380 nm that the human eye can just see. In steps of 100 nm, a distinction is made in descending length between near UV (NUV), mid (MUV), far (FUV) and the extreme (EUV) spectrum, down to 10 nm. The exact limits vary according to the literature. An alternative classification commonly used for space is UV-A/B/C, where, for example, UV-C is defined up to 280 nm and is completely absorbed by the ozone layer. UV-A effectively reaches the Earth unfiltered.

EUV lasers are essential in modern semiconductor and display manufacturing and related quality control to produce smaller as well as more powerful and efficient processors. The journey from computers that occupied a warehouse to the modern smartphone was only made possible by the continuous miniaturization of components.

Technologically similar to the chip manufacturing process is the marking of surfaces. UV lasers are used for this as well as precise drilling, due to low heat generation in many materials and thus produce clean lines. Glass and plastics present a particular challenge in processing - UV lasers are a good solution here. Lasers with VIS or IR spectra do not cut these materials or leave charred cuts.

Satellites, whether used for observing distant stars, analysing wind speeds or the climate change of our earth, need high-quality coatings to detect ultraviolet wavelengths. These must reliably separate the ultraviolet spectrum despite strong interference from other wavelengths and extreme environmental conditions to enable meaningful measurements.

UV lasers are an integral part of medical treatments, especially of the skin, as well. To ensure safe applications, special attention is paid to uniform illumination of the skin. The wavelength is selected to match the tissue to be treated and can be used in hard-to-reach areas via flexible light guides.

UV coatings from asphericon

- Wavelength range: 190 - 380 nm

- Coatings: e.g. K-Coating (355 nm), X- Coating (230 - 380 nm), Y- Coating (320 - 450 nm) and wavelength-specific antireflection coatings

- Materials: glass, fused silica, crystals

- Substrate sizes: up to 350 mm in diameter

- Process: Electron beam evaporation (EBE)

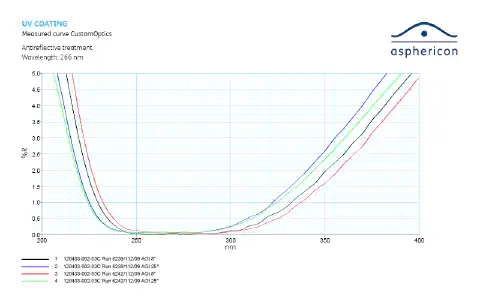

Figure: Measured coating curve for antireflection coating at 266 nm.

Optics and systems for the UV range from asphericon

Optical systems and elements for the UV range place the highest demands on manufacturing quality. asphericon not only offers the world’s largest selection of fused silica aspheres in stock, but also supports you with laser beam shaping elements (BeamTuning range) at the highest level.

The fiber collimator a|AspheriColl 355 nm enables perfect light guidance from FC/PC patch fibers in the UV range and can be used with both BeamTuning and cross-system components to meet any desired application. The a|BeamExpander UV, made of Suprasil, allows beam expansions for the use of Nd:YAG lasers [355 nm]. The two beam shapers a|TopShape and a|AiryShape ensure maximum results in all laser applications - even in the UV spectrum. Based on aspherical optics, the modular components allow uncomplicated transformation of Gaussian laser beams into different Top-Hat profiles. Spherical aberrations can be corrected with the help of all BeamTuning products. The afocal system realizes large input beam diameters, while the use of aspheric optics reduces the system size by up to 50% compared to current commercially available products. The intelligent mounting concept eliminates time-consuming adjustments, ensures flexibility and precision.

Also discover our a|FusedSilica aspheres. Optimized for a wide range of (laser) applications, as prototypes in test equipment or as standard components for beam focusing/collimation, these fused silica optics are particularly suitable for high laser powers and applications in the UV range. Selected diameters are also available as mounted optics and can be easily combined with the BeamTuning range. Our cross-system adapters allow the use with common non-system components.

Curves with specific information about the respective coating can be found on the service page for optical coating and in the download area.