Optical Metrology

Lenses and optical systems for non-contact measurement

Optical metrology describes the non-contact measurement of objects and physical quantities. In automation, production and testing processes, optical measuring techniques are used to determine differences in shape, speed or color - usually fully automatically, quickly and precisely. The advantages of this type of measurement include the short set-up times, even with frequent changes of the workpieces to be measured, optical measuring processes are quick and usually easy to perform. Compared to conventional measuring methods, optical measuring techniques continue to shine with high measuring accuracy down to the nanometer range. This is made possible using state-of-the-art sensors, high-quality optics and a high degree of automation in the measurement process. The non-contact methods also guarantee the integrity of the measuring surface during the measuring process, making it possible to scan very delicate, fragile and expensive objects without any problems. Complex objects can be measured in seconds and the measurement data can usually be captured in real time.

Diverse processes and applications

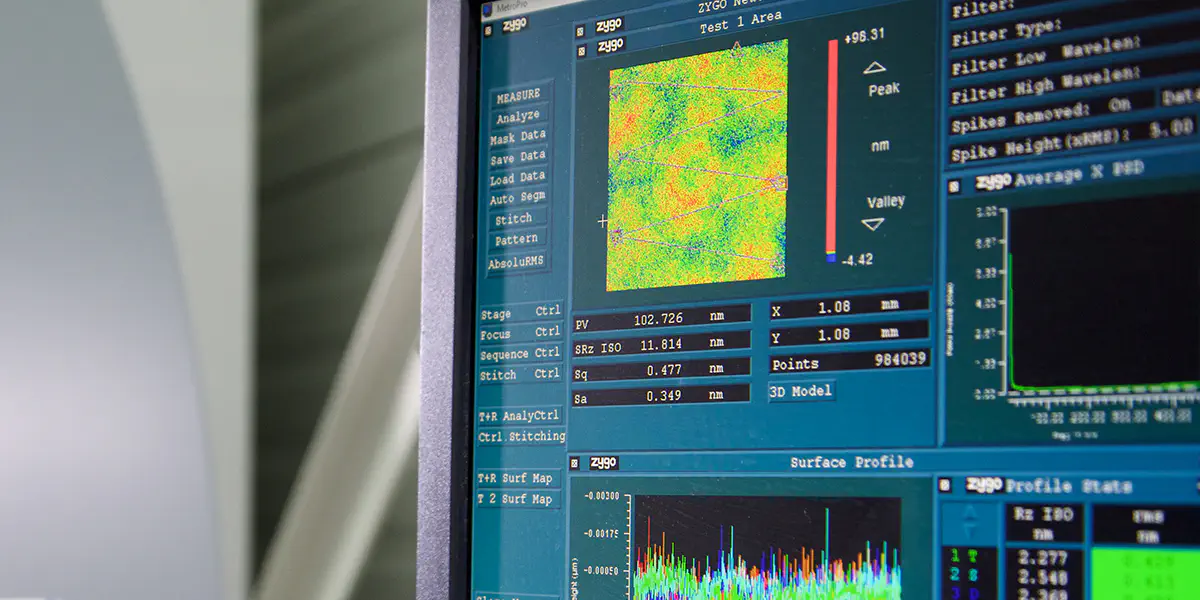

Optical measurement techniques include a variety of different measurement methods. These include light barrier systems, laser distance measurements, interferometry, optical coherence tomography or microscopy. Application examples can be found in various industries, such as the automotive industry, medical technology and above all the optical industry. In the automotive industry, for example, car body parts can be precisely assembled because they undergo optical form measurements. Thanks to optical measurement technology, medical technology is able to detect lung cancer or tuberculosis at an early stage using photoacoustic spectroscopy. The optical industry uses optical metrology, for example in the form of interferometry. Interferometry is used to measure flat, spherical and aspherical optical surfaces. The superposition of coherent light waves produces a characteristic interference fringe pattern that provides information about the optical surface of a test object to be tested.

Requirements for optical metrology systems

The optical measuring methods are made possible by high-quality optics, among other things. With aspheres free of imaging errors or freeform surfaces following the trend towards miniaturization, very high demands can be made on increasingly powerful optics, for example. The most precise reference measurements can be achieved by using first-class Fizeau lenses with outstanding surface quality. Beam shaping optics from asphericon support a wide variety of measurement techniques in the realization of high-energy and powerful beams, e.g. for special laser applications. In order to ensure long-term protection of an optical system against external influences, or to shield certain wavelengths, metrological optics require special coatings such as (anti)reflection or filter coatings. Please do not hesitate to contact us!

Individual aspheres, freeforms, systems and coatings - together we will find the right solution for your optical measurement methods.