Metrology

Precise and high-performance optics for

Optical metrology applications

In metrology, photonic solutions are used in a wide range of applications, e.g. in the automotive industry, medical technology, and optics manufacturing - from laser-based distance measuring devices to fully automated quality control and interferometric characterization of optical surfaces. A high reproduction rate of the measurement results is just as important as their accuracy and precision. Another central aspect is the imaging performance of the optical components used. Both, performance and quality of the optics used, can be increased by exact manufacturing processes and high-quality coatings.

Solutions for measurement technology from asphericon

asphericon‘s Produktportfolio für Messtechnik Anwendungen umfasst unter anderem:

asphericon’s product portfolio for metrology includes:

- Sophisticated optical and mechanical designs and initial feasibility studies

- High-quality optics such as spheres, aspheres and freeform optics with best imaging properties

- Special finishing processes for lowest surface roughness

- High quality mirrors for perfect images

- Optical systems for homogeneous beam shaping

- Durable optical coatings from UV to IR

Materials and optical coatings for metrology applications

To exploit the full potential of optical components within metrology, high-performance optics are required. The choice of material is the first important step to fulfil the specific requirements of high-precision measuring lenses or beam splitters, for example. Depending on the selected material, different manufacturing methods are used, such as CNC grinding and polishing technology optimized and patented by asphericon. By means of effective, but material-friendly processes, lenses of highest quality can be produced. asphericon has specialized in manufacturing with materials like glass, silica, metal, germanium, and IR-crystals. In addition, components made of Ig6, calcium fluoride, PMMA and silicon are processed and coated from prototype to series production.

Latest technologies are also used within the coating process. These include ion beam assisted deposition, electron beam evaporation and magnetron sputtering. The selection of the process is customer- and project-specific. Almost all spectrums can be achieved on a wide variety of materials (190 - 5100 nm). Our coating portfolio includes among others:

- Wavelength-specific coatings (short pass and long pass filters)

- Anti-reflective coatings (ARES, ARBB, ARDS, ARSBB, ARDD)

- IR coatings

- Metal coatings (Al, Ag or Au)

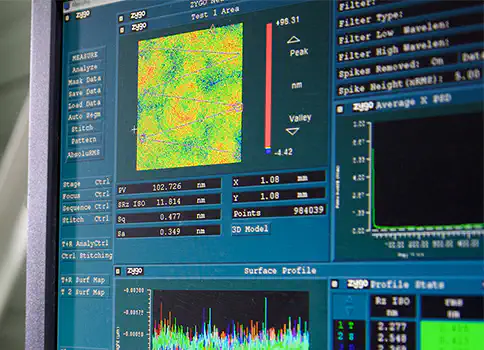

Reference measurements using an aspheric Fizeau lens

Spherical Fizeau transmission spheres are often limited within their measuring range by a small irradiation diameter . For magnification, additional adapters or beam expanders are required, smaller diameters usually cannot be covered at all. To counteract this problem, asphericon has developed an aspheric Fizeau lens as part of a customer project. Compared to classical Fizeau transmission spheres, this lens offers a significantly increased measuring range up to R/D 0.55, is much smaller and therefore lighter due to the reduced number of optics used. Without additional adapters, the 4’’ Fizeau lens covers as a single element a measuring range that could previously only be measured with a 6’’ transmission sphere.

Further information can be found in our reference story.

Additional optical applications in the field of metrology

The variety of metrology applications is accompanied by a large selection of optical components and systems, which are individually tailored to the specific requirements of the measurement task.

In the field of distance measurement, for example, highly sensitive optoelectronic sensors as well as infrared rays invisible to the human eye are used to measure the distance between two points. Depending on the metrology instrument, the evaluation of the measuring signal is based on the basic principles of triangulation or time evaluation. Indispensable for these applications are special filter layers (e.g. metallic layers or layers for beam splitters), lenses (such as e.g. spheres or aspheres) as well as highly reflective mirrors for exact detection of the existing distance.

The same optical components also form the basis for optical metrology. This includes, for example, interferometric surface measurements to determine the accuracy of production.

Optical metrology has also long been established in the automotive industry, e.g. for optical measurement of dimensions and shapes.

Optics and optical systems are also used in atomic interferometry. This measuring method based on quantum mechanics can be used, for example, to determine the earth’s gravitational field. This requires, among other things, powerful beam shaping systems, such as the a|TopShape, to be able to direct a laser beam in the desired way onto atoms for deceleration.