Metrology

Precise – more precise – asphericon

The most accurate measurement results from the specialist

The latest tactile and interferometric measuring instruments allow the flexible manufacturing of aspheric optics at the highest technological level. A specially developed and integrated database system enables measurement results from all manufacturing steps to be documented, evaluated precisely, and accessed at any time. A wide range of measuring instruments is used to achieve accurate measuring results. Our experienced team is looking forward to your project!

Metrology at asphericon at a glance:

- Tactile measurement up to diameters of 260 mm

- Full-surface non-contact measurement up to 420 mm

- Non-contact center thickness measurement

- Roughness measurement Ra < 0.5 nm RMS, measuring field up to 1 x 1 mm

- Measurement of freeforms: form and positional tolerances, roughness

- Measurement/position check of mounts, mounted optics and complete systems

- Confocal 3D defect characterization

Our measuring instruments

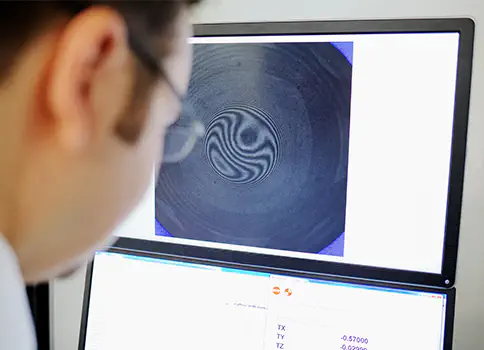

MarOpto TWI

- Fast interferometer in the production environment for surface form and radius measurement on aspheres, RMS reproducibility of < 1 nm

- Most accurate recording of medium and high-frequency errors and coma

LuphoScan 260 and 420

- Fiber optics based multi-wavelength-interferometry (MWLI®)

- Measuring range: 420 mm (diameter) by 100 mm (height)

- Longitudinal resolution: 0.1 nm

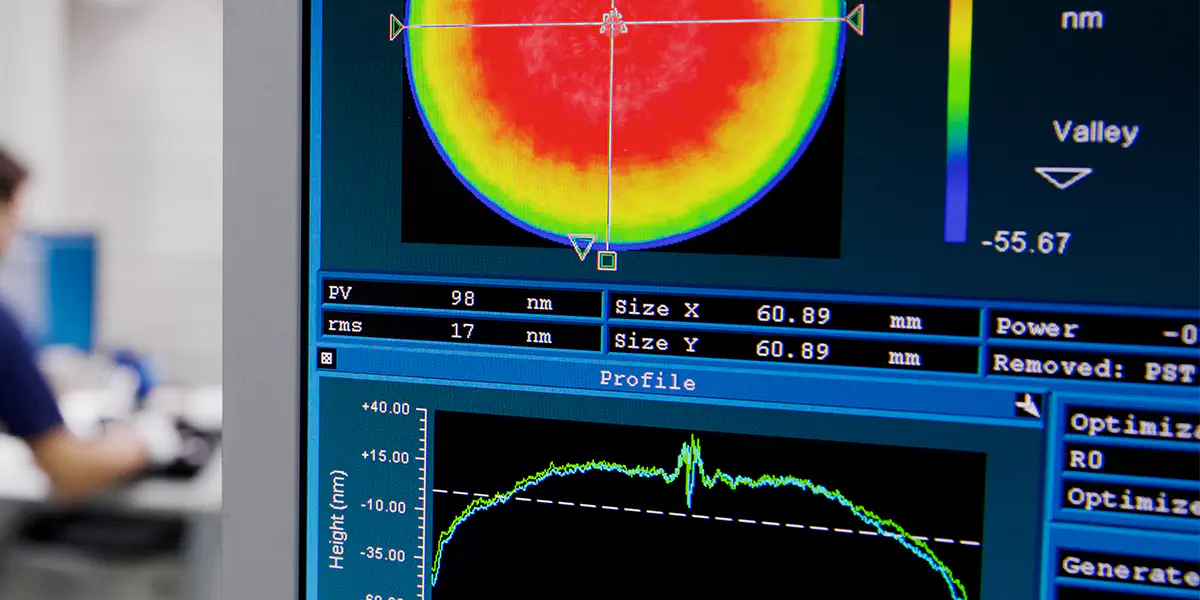

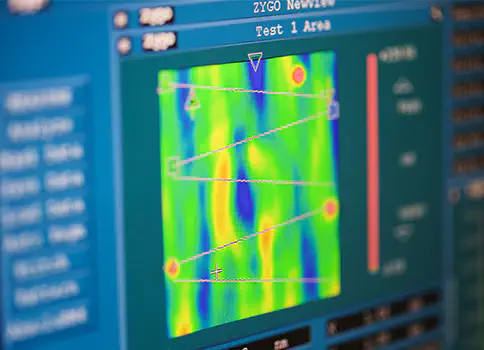

Zygo Verifire AsphereTM

- Laser based, 3-dimensional, mechanical phase shifting interferometry (6″ Fizeau interferometer) combined with heterodyne displacement interferometry

- Capability: measurement of the surface form deviation and radius of curvature of aspheric, spherical and flat optics

- Aspheric measurement performance up to 60 nm (λ/10)

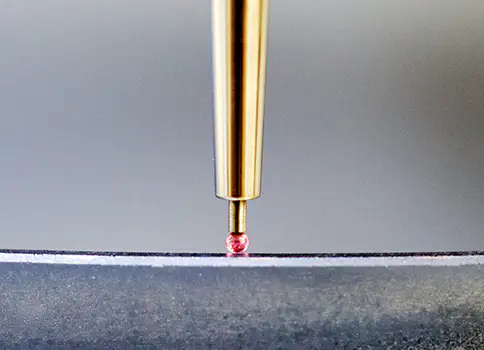

MarSurf LD 120 MarWin

- Two-dimensional measuring of optically rough surfaces

- Exact reproduction of aspheres, based on a resolution of 2 nm (0.08 μin) and form deviations of less than 100 nm (4 μin)

MarSurf LD 260 Aspheric

- Highly accurate 2D / 3D measurement of optical components

- Direct measuring range up to 260 mm

- Maximum diameter up to 400 mm

- Resolution: 0.8 nm

MarForm MFU 200 Aspheric 3D

- High precision 2D / 3D measurement

- Wide measuring range up to 260 mm in diameter

- Vertical resolution of 1 nm and form deviations of <100 nm (< +/- 50 nm)

- Centering accuracy within the micro- to submicrometer range

Zygo NewViewTM 7100 and MarSurf WM 100

- Measuring of roughnesses on aspheric surfaces up to 0.5 nm

Your request

Always the latest news from asphericon