Imaging and Display

High-performance optics and systems

Optical applications for imaging and display

The market for imaging and display solutions is based on sophisticated optical image and data processing systems. The combination of modern software technology with high-quality optical components, such as camera or projection systems, is considered a key technology in some areas. This helps, for example, to optimize production processes, to record and evaluate workflows holistically and to support communication in the field of diagnostics. The specific requirements of optical systems must be recognized in a targeted manner and optimally implemented in production processes.

Solutions for Imaging and Display from asphericon

Solutions for Imaging and Display from asphericon

- High-end aspheres for perfect image quality and high-resolution images

- Customized mirrors

- Compact freeform optics for image processing systems with reduced size

- Antireflection coatings or wavelength-specific filter layers

- High-End Finishings for minimum roughness values, better imaging and focusing of the incident rays

Materials and coatings for imaging and display applications

As an optics specialist, asphericon’s manufacturing expertise ranges from customized mirrors to individual high-end aspheres up to complete photonic systems. The material to be used ultimately determines the underlying manufacturing process. asphericon processes:

- Various types of glass and silica,

- PMMA,

- IR glass/crystals,

- Metals,

- Other materials on request

Surface accuracy can be optimized for all materials. An additional increase in effectiveness is achieved by coating the surfaces, e.g. with anti-reflection coatings or wavelength-specific filter layers. Optical oatings are offered for all wavelength ranges (UV-VIS-IR) and materials. More information about our coating options.

Best image quality through High-End Finishing processes

Optics and optical systems must be able to detect even the smallest differences between nominal and actual shapes, e.g. in the production area. Prerequisite for this are, among other things, high imaging qualities. To achieve this, asphericon offers a range of so-called High-End Finishing processes. The aim of these processes is to minimize surface roughness Overall, we differentiate between three technologies:

- ION-Finishing™-Technology,

- Magnetorheological Finishing Technology® (MRF for short) and

- Ångström-Polish developed by asphericon.

High-End Finishings enable roughness of up to 5 Å (Rq according to ISO 10110) on optical surfaces and create enormous freedom of action for numerous application requirements. The decision which technology to use depends on various factors. ION-Finishing is particularly advantageous for polishing materials that should not meet chemical influences (e.g. contact with water). MRF-technology is characterized by a wide range of corrections in the short and long wave range and is therefore also regarded as a kind of “all-rounder“. The Ångström-Polish convinces with particularly low residual scatter and minimal roughness

Minimum system size due to freeform optics

A trend towards miniaturization can be seen in the design and construction of industrial camera systems, for example. Freeform optics offer one possibility for system reduction. A prerequisite for this is a not inferior imaging quality compared to the existing optical system as well as compatibility with other optoelectronic components used. Due to state-of-the-art production and measurement facilities, asphericon can manufacture freeform optics that are in no way inferior to aspheric lenses in terms of imaging quality. At the same time, the complex design allows a significant reduction of space and weight compared to a conventional design for the same optical task. Find out more about the possibilities of supplementing your optical system with freeform optics.

Specific areas of application

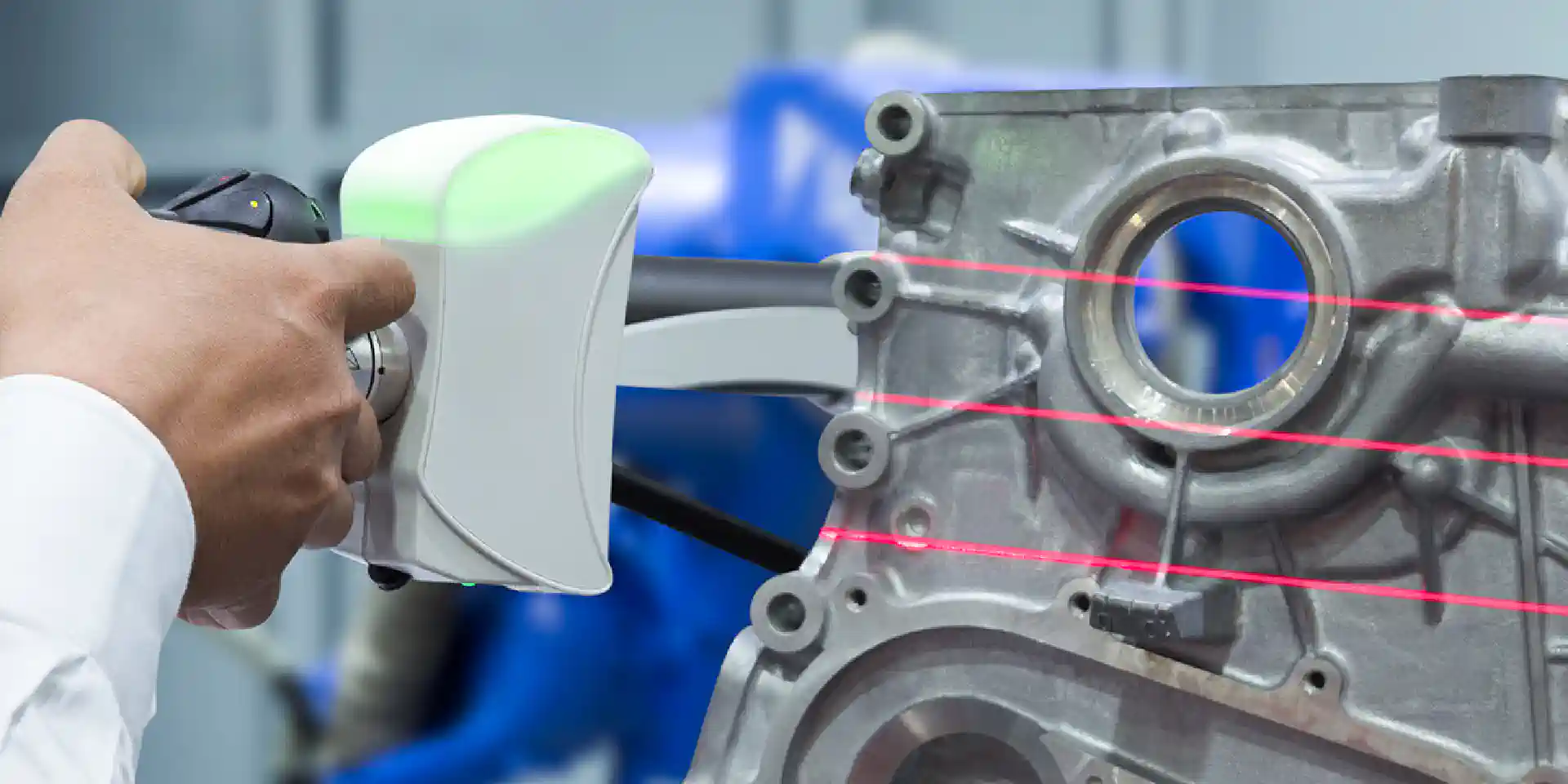

Image processing is based on software evaluation of the recordings of modern camera systems. In addition to the inspection and optimization of production processes, various codes can be read in and entire components identified. Furthermore, a trend towards three-dimensional representation, made possible using lasers and sensors, is developing. Sophisticated optics, such as aspheres or freeform optics, enable high imaging quality and can also reduce the size of existing systems.

Another application area is industrial laser projection. Using modern projection systems, outlines are projected onto the surface of various materials, e.g. in production, to check positions. Industrial laser projections are also used in other areas such as navigation. For example, to project flight information data onto the head-up display of a pilot. Highly reflective mirrors, compact beam shaping systems or stable optical coatings are required for this purpose.

The most important component for obtaining information with the help of industrial camera systems are high-resolution lenses. Consisting of optics, such as spheres or aspheres, these must be able to withstand continuous use, sometimes even high temperatures and vibrations. Best optical imaging properties can be achieved by means of High-End Finishing processes.