Laser Marking

Beam shapers, mirrors and coatings for effective bundling of light energy

Laser marking has become an indispensable part of the industrial and commercial environment. As a reliable processing step, they allow recognition and traceability by marking a wide variety of products and production pieces. Be it a company name on a ballpoint pen, a trademark on cutlery, symbols on switching units within a vehicle or a reference number on a high-performance optical system. As a permanent companion in everyday life, laser markings can be found everywhere. The permanent, abrasion-resistant marking of various materials such as metal (aluminum, gold, stainless steel, etc.), plastics (PMMA, polycarbonate, etc.), wood, lacquers or foils is always in the foreground. Laser marking involves various processes:

- Starting,

- Ablation,

- Foaming,

- Engraving and

- Discolor.

General structure of a laser for marking/labelling

Of course, a laser medium is at the center of the object labeling. This emits energy in form of light, while energy is pumped in via a pump. An additionally installed resonator, which in the simplest case consists of two parallel mirrors, amplifies the resulting light radiation. Between the mirrors, one partially impermeable and the other impermeable, the light waves are reflected back and forth until they emerge from the partially permeable mirror as a bundled laser beam. The laser beam produced in this way can then be used for various purposes, such as laser marking.

Laser types and applications

Depending on the material to be marked, different types of lasers are used: A fiber laser, for example, is preferably used to mark metals by engraving. ACO2 laser is often used for marking glass and plastic. Industries in which laser marking is an integral part range from automotive industry, electrical industry and medical technology to the packaging industry. Since there are no mechanical resistances to the laser during marking, high processing speeds are possible, which leads to considerable time and cost savings. Laser marking is a pioneer in marking due to its ability to achieve the smallest, most precise markings that are durable and resistant to various environmental influences. Advantages such as contactless material processing save costs for milling cutters and drills, additional materials such as ink are not necessary. High operational reliability, low maintenance requirements or high flexibility regarding motifs and materials make laser engraving an indispensable medium of our time.

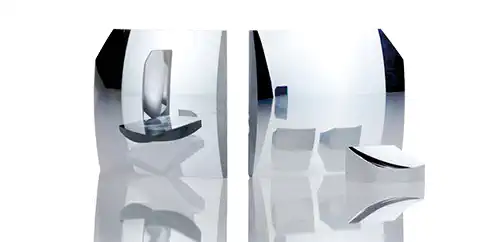

asphericon offers unique and effective solutions for the many different optical components. Our beam shapers, mirrors and coatings allow fast and effective bundling of light energy. A wide range of different lenses, from the sphere to the asphere to the axicon, lead to the powerful use of your lasers.