Research and Development

From components to systems and services

From components to systems and services

Optical components can be used in a variety of everyday, technical and industrial applications. The shapes, materials and finishing possibilities of optics are as extensive as their use. As a reliable partner, asphericon offers custom-made solutions for your individual optical requirements; from optical design to a targeted development and manufacturing process to after-sales service. Let our products convince you with their outstanding quality, highest precision and long-lasting functionality.

Solutions for research and development from asphericon

- High-quality optics such as spheres, aspheres and freeform optics with best imaging properties

- BeamTuning/BeamShaping components for optimized illumination (e.g. in fluorescence microscopy)

- Durable optical coatings from UV to IR

- High-end finishes for optics with low roughness in the Angstrom range

- Sophisticated optical and mechanical designs as well as initial feasibility studies

Groundbreaking technologies

A specially developed and patented technology for the control of CNC grinding and polishing machines, with the ability to simulate machining processes, forms the manufacturing basis at asphericon. Whether prototype construction, small quantities or series production: Thanks to our unique technologies, we produce optics for a wide variety of materials and geometries with high precision for all wavelengths, from spherical lenses to asphere, acylinders, plano optics and diffractive optical elements. Each asphericon optic contains the compressed knowledge and experience from a multitude of challenging projects that can perfectly complement your individual project.

Ultra-precise for highest requirements

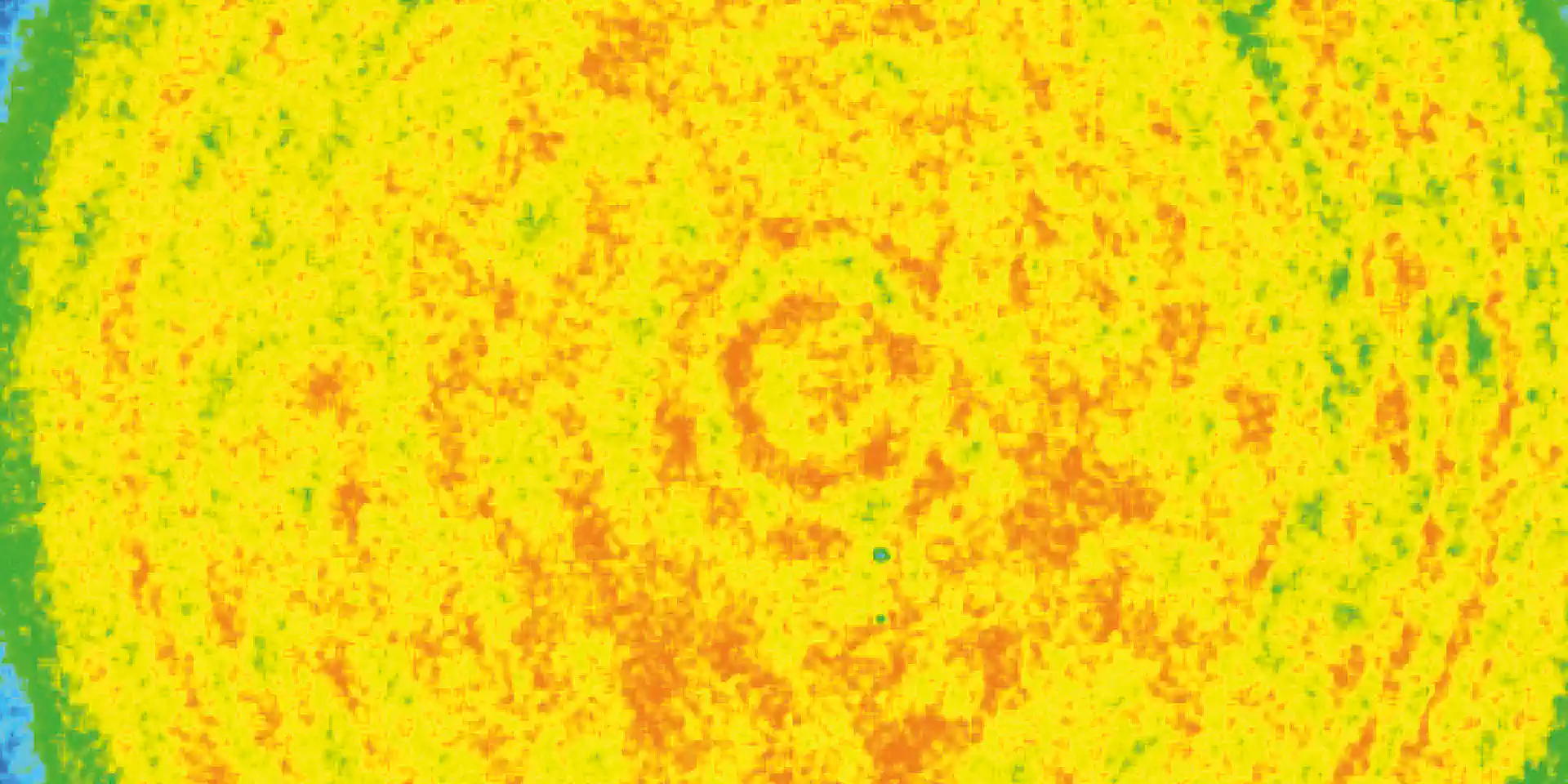

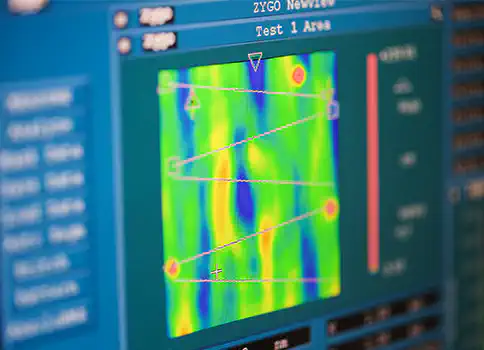

At asphericon, the efficiency of an optical system can be further increased by means of high-end finishing processes by correcting local shape defects. Ultra-precision machining includes ION-Finish, Magnetorheological Finishing-Technology (MRF) and the specially developed asphericon Angstrom-Polishing. The surface correction methods achieve roughness values of up to 5 Å (measuring range 1000 x 1000 µm, Rq according to ISO 10110). Our coatings can additionally refine optical elements for a wide variety of applications - no matter whether it is an optic produced by asphericon or an optical component provided by you. We offer high-quality surface coatings across the entire spectrum, from UV to the near infrared range.

Design and manufacturing quality that exceeds expectations

Convince yourself of the quality of our ISO-tested optics (production chain certified according to DIN ISO 9001) and get a variety of customer-specific optical elements (Custom line) and stocked standard optics (StockOptics line). The StockOptics range available in our webshop includes precision-polished aspheres, axicons and acylinders, combined with the cost benefits of mass production. Selected lenses are also available as mounted versions and can therefore be integrated into applications even faster.

For individual design requirements, our in-house optical design department will be happy to advise you on everything from analysis and conception to final implementation. In addition, asphericon offers numerous optical services. These include, for example, optical characterizations based on high-resolution wavefront measurements or optical measurements that can be carried out quickly and easily thanks to extensive tactile and interferometric measuring instruments.

Optics of the future

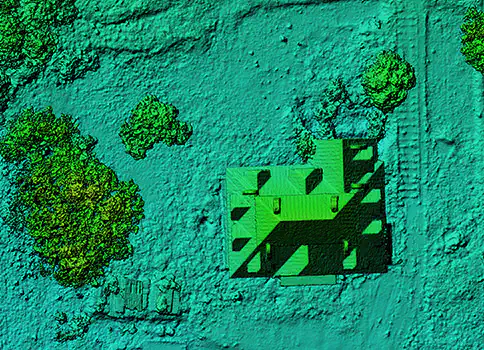

asphericon is also dedicated to research and further development, for example in the field of freeform optics. Following the trend towards miniaturization, asphericon’s freeform systems are convincing not only because of the unique complexity of optical surfaces and small number of optical elements required, but also because of their excellent imaging properties. This opens completely new possibilities in the field of optical design, as they are free from the limitations of traditional manufacturing geometries.

Your request