Laser applications

Durable optics and systems

Laser applications in science, health, and industry

Whether laser cutting, ultra-short pulse lasers or the need for OEM-solutions - lasers and related applications are an integral part of numerous production-related industries. Especially in the field of material processing, laser-based systems can be used in many ways. In addition, lasers are used in medicine, e.g. for tattoo/hair removal, laser projection or quality control. Homogeneous beam intensities and shapeable beam diameters are essential for effective laser applications. Mirror systems, thermally resistant lenses or optical coatings form the basis for this.

Solutions for laser applications from asphericon

asphericon’s product portfolio for laser applications includes

- Optics (e.g. aspheres, spheres, freeform optics), mirrors and powerful systems for maximum laser power

- High-End Finishings for ultra-precise optical surfaces

- High-precision Gauss to Top-Hat beam shapers and axicons for the generation of ring profiles

- Optical coatings for all wavelengths that provide desired spectral properties

- Optics and optical coatings with resistance to challenging environments

- Objective lenses for laser material processing

Materials and geometries for laser applications

Laser applications require a variety of high-quality optics, from beam expanding systems to semi-transparent mirrors. In the spectral range from UV to IR, the material must be able to perform its specific task while achieving the best performance results. The processing method also plays a decisive role. Only by means of high-precision and modern production facilities optics, assemblies and systems can be produced with the smallest shape deviations. At asphericon you can obtain optical components for your laser application from various types of glass, silica and ceramics, IR materials and metals (other materials on request). In manufacturing we are specialized in production by grinding and polishing, diamond turning as well as precise High-End Finishing processes.

In addition, we can also supply you with special designs with unusual geometries (e.g. with bevels, drill holes or steps) as well as optics in various processing stages (e.g. cemented, edge-coated and/or laser-marked). The measurement and documentation according to your requirements is also carried out at the highest level.

Homogeneous intensity distributions

If Gaussian intensity profiles are used in laser material processing, such as laser cutting, the quality of the cut edges of a workpiece is reduced. The reason for this is the shape of the Gaussian profile, which has high intensities in the center and low intensities at the edges. A similar problem arises when attempting to structure the surface. A uniform melting of a workpiece is not possible due to the lack of homogeneity of the laser beam. A simple and effective solution to increase the homogeneity of a laser profile is to use Top-Hat profiles. These can be generated with beam shaping systems from asphericon, for example. Using the beam shapers a|TopShape and a|AiryShape, Gaussian beams can be transformed into different, homogeneous beam profiles, e.g. into a Top-Hat profile to optimize the cut edge quality for a uniform heat input into a surface to be treated or even into Donut profiles. More information about homogenization of beam profiles can be found on the BeamTuning product pages.

Optical coatings for laser applications

A wide range of optical coatings can be used within laser applications. The coating must cover a wide spectral range to transmit or block beams in a wavelength-specific manner and to protect the optical components from high intensity effects and the associated high temperatures (dielectric layers). In addition, laser application-based coatings serve to guarantee images in the best possible way (e.g. anti-reflection coatings). Metal-based mirror surfaces can also be a good alternative to more expensive reflectors. asphericon coats optics and systems up to substrate sizes of up to 300 mm diameter. Our range of services includes:

- Antireflection coatings

- Dielectric layers with reflections greater than 99 %

- Mirror surfaces based on metals (e.g. Al, Ag or Au)

- Filter layers and

- Coatings for beam splitters

Specific laser applications

Laser-based systems enable efficient and time-saving processing procedures within a variety of industrial processes. The optical components used must be adapted in best possible way to individual specifics of the laser application. One possible application of laser-based systems is laser scanning. Using high-quality beam shaping systems and highly reflective mirrors, 3D laser scans can be carried out, for example, to carry out a reliable target-actual comparison of products to be manufactured in quality control.

Within laser marking, optical systems are characterized by a high degree of flexibility regarding the shape of the marking to be created. Trademarks can be engraved quickly and effectively on cutlery, for example, or high-performance optics can be provided with a reference number.

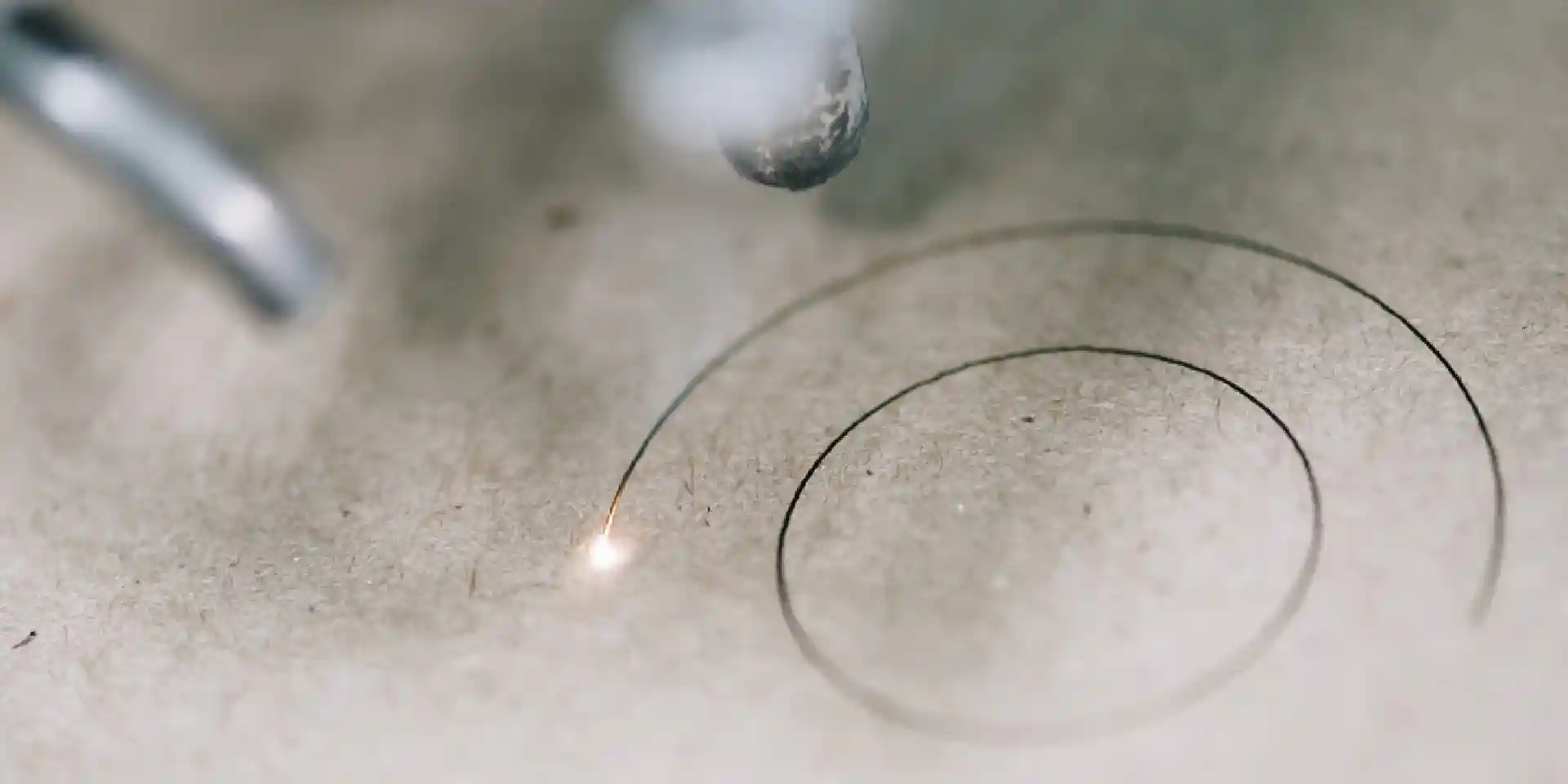

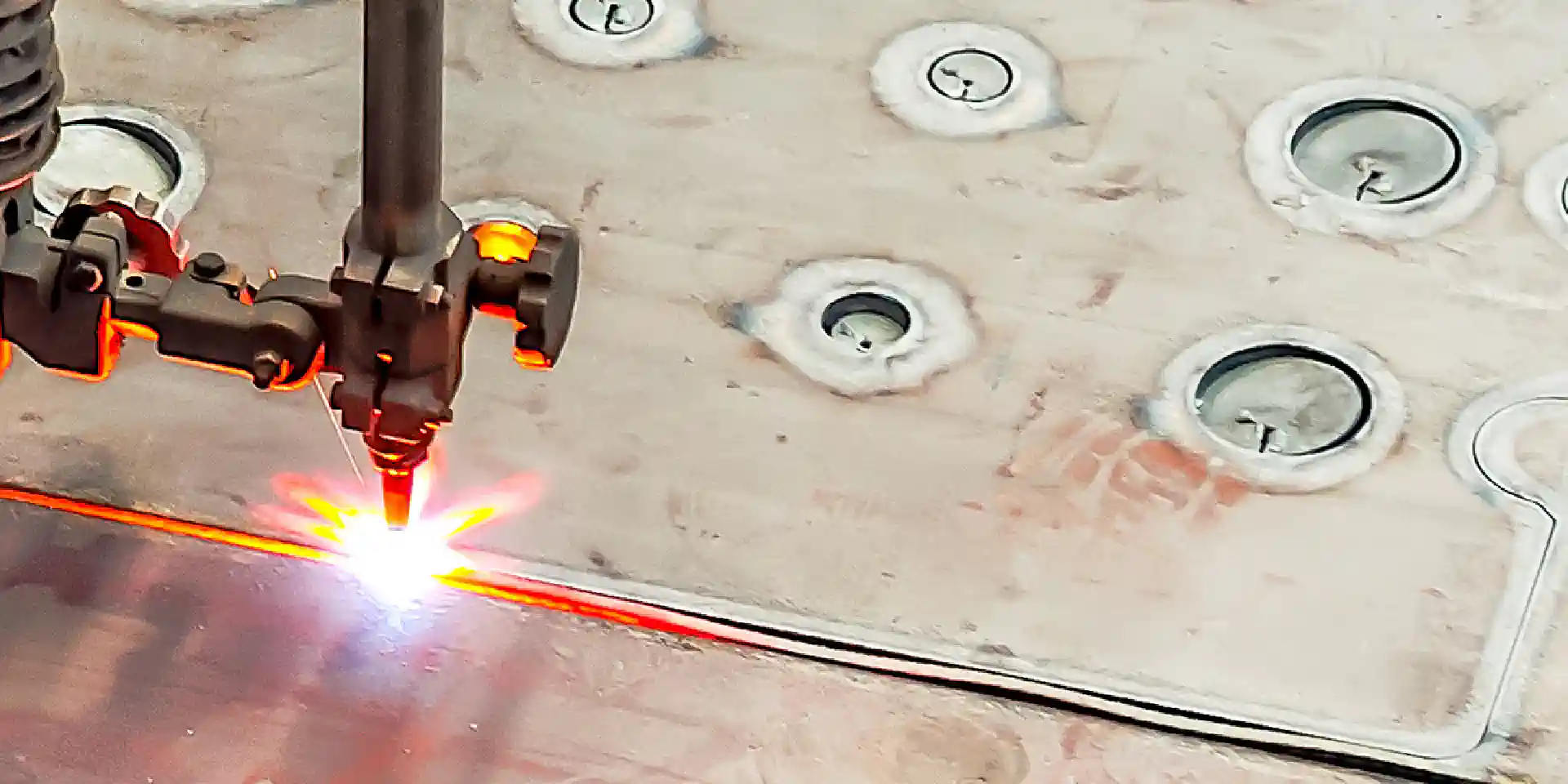

In the field of laser cutting, as a thermal cutting process, lenses are required that provide constant performance under the influence of intense heat. At the same time, they must provide the best imaging quality to generate a precise cutting edge during the cutting process. One way to maintain the imaging quality at a constantly high level is to use aspheric lenses, which are additionally coated with a thermally resistant coating. Another option is the improvement of the lens surface by means of a High-End Finishing, which is also used for lenses within laser welding. Thanks to high-quality optical components, the joining process is characterized by clean weld seams, which have a high-pressure density as well as a high load capacity. This laser process is used to produce medical devices, but also in the automotive and marine industries.

In the field of laser material removal, laser-based systems are used to remove layers from surfaces. This is intended to structure, smooth, or minimize the thickness of the layer. The low ablation can be made possible by the wavelength specificity of the laser due to special filter layers. A surface structuring serves, for example, to roughen a surface for better bonding of an adhesive.