Industrial Camera Systems

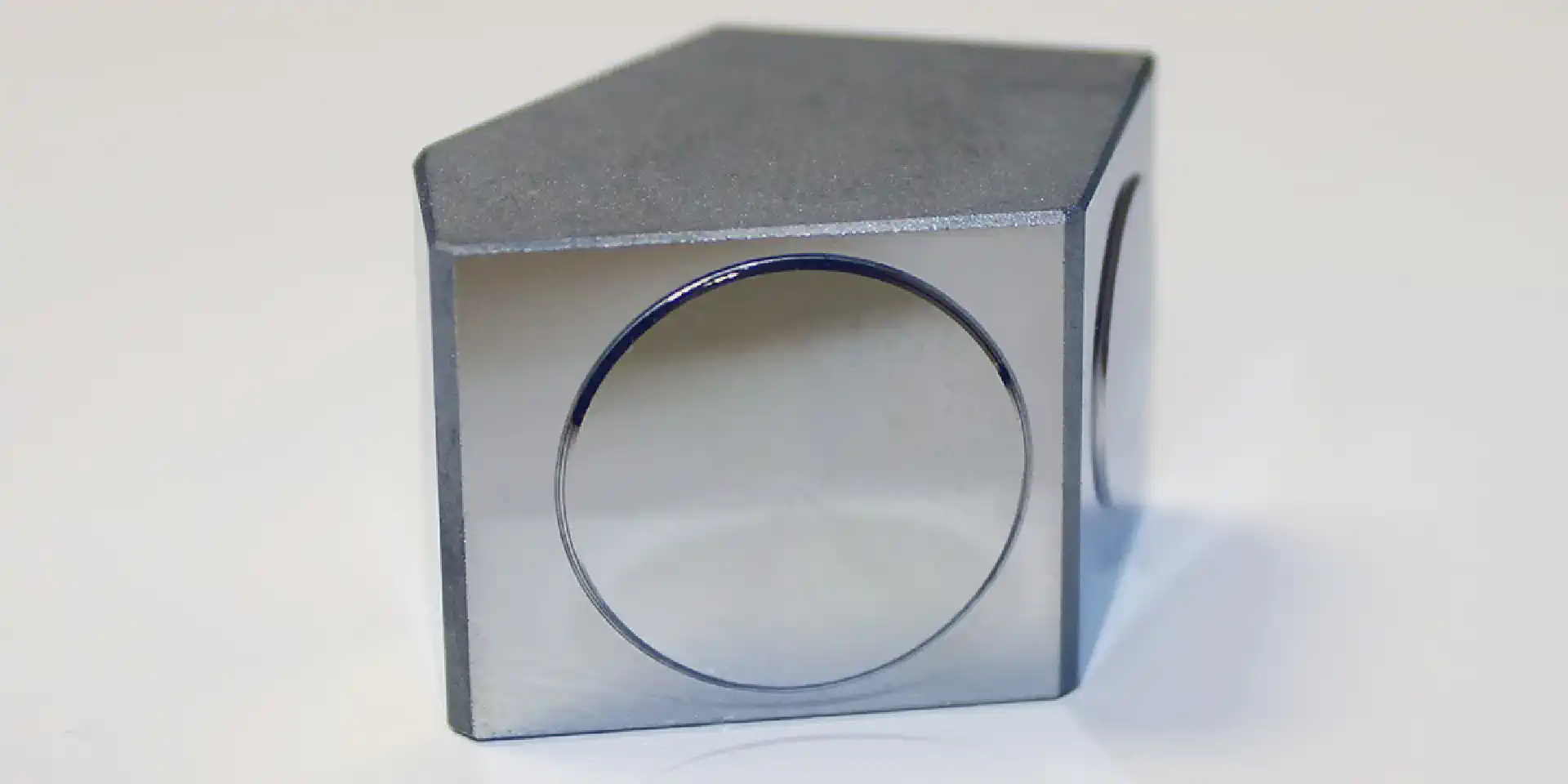

Durable aspheres and freeforms for high quality lenses

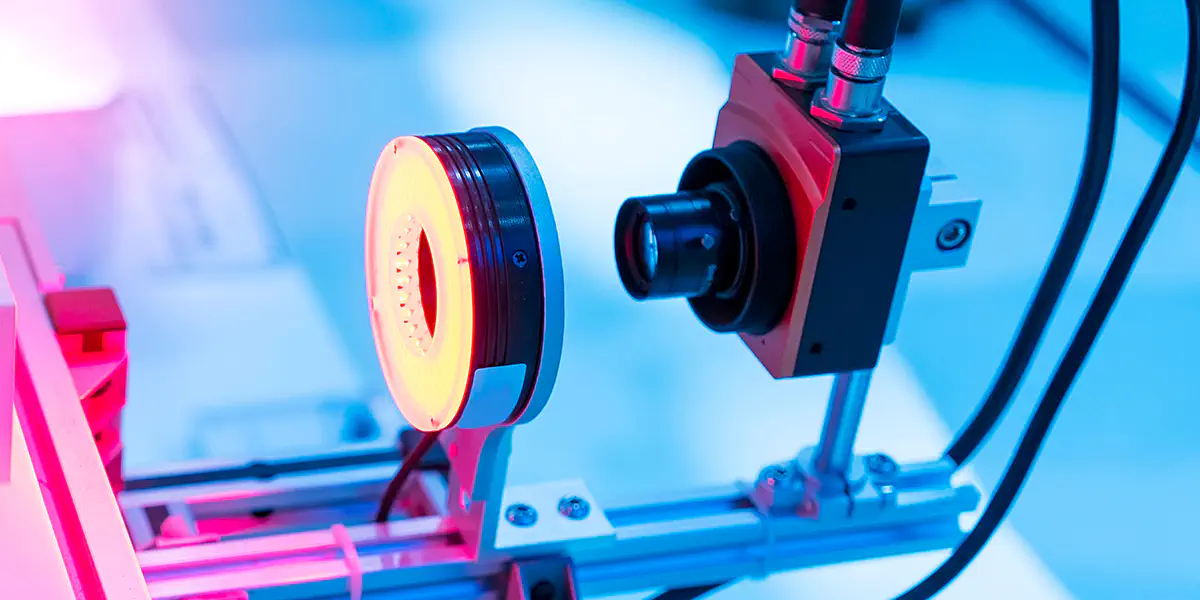

Industrial camera systems are used to capture images, observe processes, transfer generated data to a software unit and, if necessary, store it. The most important component is the lens. Its task is to collect the light scattered by an object through a lens or lens system and focus an image on a light-sensitive sensor. The sensor converts the light signal into electromagnetic radiation and transforms its intensity and frequency into data. The data is evaluated by a software unit and used for the respective process optimization or evaluation.

Diverse applications, high requirements

The fields of application of industrial camera systems are manifold and cover areas such as quality control, robotics or the pharmaceutical industry. The demands placed on industrial camera systems and the optical elements they contain are correspondingly high. They have to withstand the most difficult conditions, such as high temperatures, vibrations and continuous use. They should always deliver reproducible results and guarantee a high degree of reliability. Factors such as dynamic range, resolution or frame rate are also of great importance.

The lens as the most important component of the system

Industrial camera systems include a high-quality lens to focus the necessary information on the sensor. The choice of the right lens depends on the one hand on the measuring task and the image field size, and on the other hand on the desired resolution. Industrial lenses are available in different versions. A frequently used lens, for example, is the entocentric lens, which has a fixed focal length. It depicts objects of the same size at different distances and in different sizes: smaller in the distance and larger in the vicinity. Normal lenses are therefore not suitable for applications in the measuring range, but the fixed focal length allows the object area to be captured to be adjusted very well. The areas of application for entocentric lenses are, for example, assembly checks or the reading of barcodes. There are also lenses with which the focal lengths can be adjusted within a fixed range by means of a manual or motorized zoom function, as can the aperture or autofocus function. These zoom lenses are used for strongly changing distances.

Another frequently used lens is the telecentric lens. This has the particular advantage that objects viewed at different distances have the same image size. Since the main beams in the object and image space are guided parallel to the optical axis, the objects of different distances imaged on the image plane are of the same size. This advantage can be used for objects to be measured on conveyor belts, e.g. if they are not exactly positioned. Telecentric lenses are particularly suitable for more demanding optical inspection procedures.

In general, the lowest possible distortion and the best imaging properties are important criteria for functional lenses in industrial camera systems. Lenses or lens systems form the basis for this. High-quality aspheres are suitable for example through the compensation of geometric distortions - such as spherical aberrations or image field curvature at larger aperture angles - as well as through best imaging properties for an optimized lens in systems. Objectives can also gain in effectiveness and performance through so-called freeform surface systems. Following the trend of miniaturization, best optical control possibilities can be achieved by means of freeform lenses in a compact size at the same time.