Surface Texturing

Laser material ablation in the Nano range

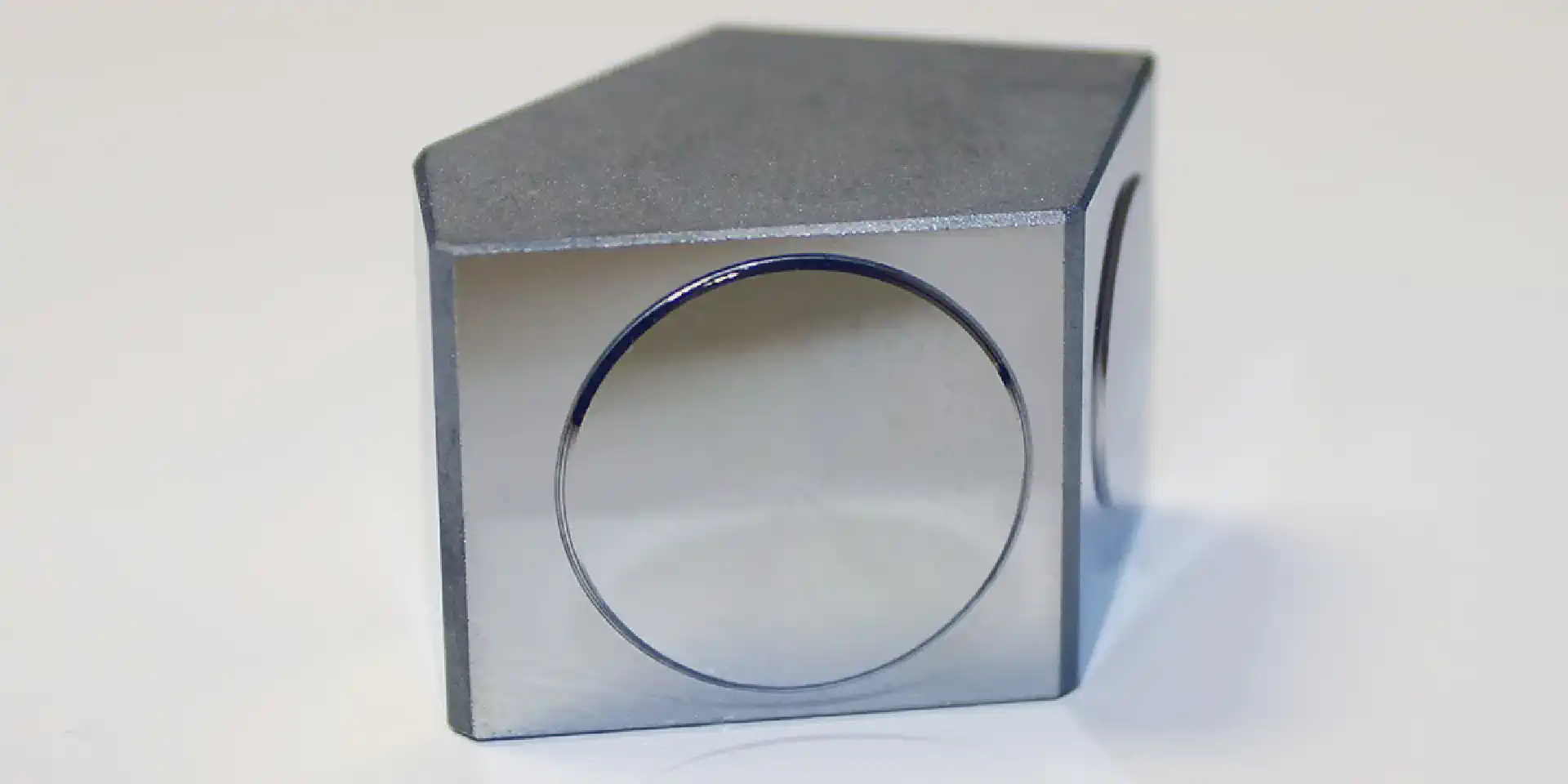

Surface structuring is used to create a wide variety of structures on numerous materials, such as plastic and metal. These structures can be made up of geometric shapes to create a certain visual impression or pattern, or of irregular structural units, such as a brushed wooden surface. A laser processes the existing surface and enables targeted material removal, which can result in roughening or smoothing of the surface, for example. The removal of the material generates individually desired roughness values, which serve in further production steps, for example the optimized adhesion of adhesive or lacquer, on different workpieces. The processing of individual pieces as well as series production is possible in detail and with high precision.

Targeted material removal for surface structuring

The respective surface structure is saved as a 3D model using software. Depending on the model, the laser can easily generate micro- and nanostructures on various material surfaces using short, high-energy laser pulses. High-precision optics guarantee an effective laser beam and the resulting high level of detail in material removal. From ultra-precise lenses for focusing the laser beam to on-axis or off-axis mirrors for maximum reflection and bundling of the resulting laser beam.

Advantages of laser surface structuring

The great advantage of laser-based material ablation compared to the mechanical process lies in the plannable precision of the resulting ablation. One example is tearing aids on packaging: The high precision of the laser-supported tear-off seam contrasts with the uncontrolled result of a mechanically produced seam. A further field of application is the removal of special foils to optimize the respective workpiece surface. The different absorptions of the films can be dealt with by means of lasers, whereby neighboring layers are spared from material removal. The shape of the surface to be machined, as well as the size of the surface, are almost unlimited. Large, thin sheets up to complex freeform surfaces can be processed punctually as well as over the entire width by laser and provided with a certain structure.