The laser-induced damage threshold in high-power laser optics

causes, assessment, and how to combat it

Content

Optical components such as those found in all sorts of high-tech applications usually have a complex manufacturing chain involving several abrasive stages. During a series of machining processes, the structure or composition of the material used is abraded to produce optical substrates with high-quality surfaces and excellent characteristics. However, these manufacturing operations can also cause microscopic defects and local inhomogeneities that may lead to laser-induced damage (LID) and severely impair the performance of optical substrates under high stress. This is especially true for coated high-power laser optics if, for example, they’re irradiated at high intensity. The higher the peak pulse power they’re exposed to, the more they need to be optimized if they’re to withstand high laser intensities without suffering any damage. Lately, researchers have been exploring the causes of LID and how it can be reduced or even completely prevented.

This series of blog articles on the laser-induced damage threshold (LIDT) will start by addressing the causes of LID during manufacture. It will then explain how this damage is evaluated and classified, and introduce ways of reducing local inhomogeneities. The second part of this series will consider the positions and morphologies of LID, and describe the main measuring techniques used to determine the LIDT.

Does subsurface damage cause laser-induced damage?

Hard, brittle materials such as ceramics, glass and carbides are widely used in high-performance applications due to their excellent physical and mechanical properties. However, their hardness and strength make them difficult to process. Moreover, high system integrity is essential for high-power laser and lithography systems. As well as great dimensional accuracy, ultra-smooth surfaces in the low Ångström range (Angström polishing) are required.

Abbreviations

| LIDT | Laser induced damage threshold |

| LID | Laser induced damage |

| SSD | Subsurface (mechanical) damages |

| OCT | Optical coherence tomography |

| MRF | Magnetorheological finishing |

| IBF | Ion beam figuring |

| UAG | Ultrasonic-assisted grinding |

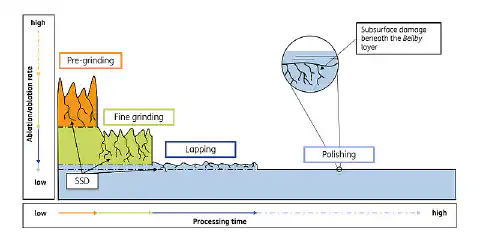

These high-performance components are manufactured using precise, deterministic machining processes, such as grinding, lapping and polishing. The snag is that each new stage may induce micro-defects and cracks in the material. Fig. 1 illustrates the manufacturing chain for optical components and the crack damage seen after each stage. Due to the brittle nature of amorphous materials, micro-defects can occur on the surface and also extend several hundred micrometres inside the material. These internal defects are referred to as subsurface (mechanical) damage (SSD). Such crack structures are particularly detrimental to the performance and lifetime of optical components and can significantly reduce the LIDT.

Fig. 1: Conventional process chain for the manufacture of optical components including close-up of the residual crack damage

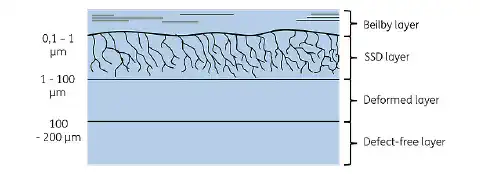

The diagram in Fig. 2 shows a highly magnified view of the layer-by-layer structure of an annealed glass surface. During the polishing process, a closed layer is formed, which flows into the valleys of the roughness profile as a partly melted material, thus ‘concealing’ the SSD. This is known as the Beilby layer. It may have an amorphous or microcrystalline structure, and it consists of a highly hydrated, work-hardened material. In addition, it may contain foreign substances or impurities that can cause highly absorbent, photoactive effects. Below it is the layer of SSD (i.e. the defective layer) containing cracks up to 100µm deep. It can weaken the material and also act as a reservoir for impurities.

Fig. 2: Structure of an annealed glass surface

The type of crack paths, their depth, and the resulting surface roughness depend very much on the process parameters (cutting speed, grinding pressure, grain size and shape, grinding and polishing time) as well as on the material’s mechanical properties. Especially when it comes to high-precision applications, it’s important to quickly reach the zone of defect-free material starting from the Beilby layer. Therefore, as shown in Fig. 1, a multi-stage process consisting of pre-grinding, fine grinding, lapping and polishing with suitable parameters is usually applied during the manufacturing process. The central aim of this is to eliminate or at least reduce crack damage as much as possible in each stage. This is because the lower the SSD, the less effort will be required in the subsequent, sometimes more time-consuming steps (e.g. polishing).

Defects and SSD also affect the service life of optical coatings. These are applied to optical components after manufacturing, and enable reflection and transmission characteristics to be adapted to the specific application. However, they often suffer from serious structural defects owing to increased surface absorption during intense laser irradiation, which frequently damages the optical surface. Besides the laser damage threshold (LIDT) and the coating quality, SSD also impairs the achievable imaging quality and the mechanical properties of optical components.

Characterization of subsurface damage

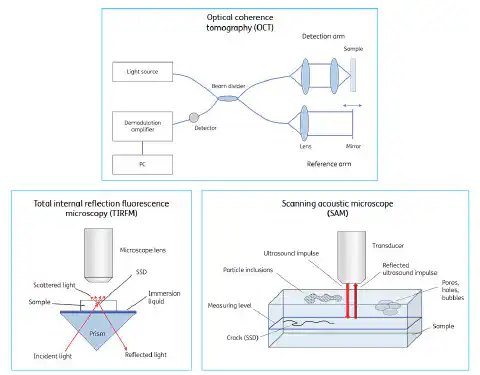

With the surface integrity of optical components expected to meet ever more exacting tolerances, damage on and below the surface needs to be characterized as precisely as possible. These days, various damage detection techniques are used. As well as revealing the extent, type and position of SSD, they also provide guidance for the subsequent processing stages. These methods can be divided into non-destructive and destructive techniques. Non-destructive methods primarily include optical techniques such as microscopy, scattered light and fluorescence measurement, and white light interferometry. Other ways of gauging SSD non-destructively are prediction models and acoustic microscopy. Another promising non-destructive method is OCT (optical coherence tomography), a three-dimensional technique which delivers both quantitative information on crack depth and qualitative information on crack morphology. The diagrams in Fig. 3 illustrate how three of these methods work.

Fig. 3: Diagrams showing three different non-destructive measurement methods used to detect SSD

In addition to the above-mentioned techniques, destructive measurement methods are primarily used in industry and research. They mainly include chemical or mechanical processes, such as ion beam etching and various polishing processes. Their advantages are that they remove severe defects and eliminate residual stress in the material by means of etching and spot polishing. The polishing technique known as magnetorheological finishing is currently the preferred method for detecting SSD, and is sometimes used in conjunction with atomic force microscopy (MRF wedge technique). As well as removing residual defects, this approach also provides information about crack profiles and paths.

Processes to reduce and avoid subsurface damage

The paramount aim when manufacturing modern optics is to avoid and reduce crack structures and defects. Accordingly, various SSD-reduction methods have been developed. In particular, spot polishing processes such as MRF polishing or IBF (ion beam figuring) can be used after chemical etching to improve smoothness and LID resilience. Furthermore, special chemical process chains known as advanced mitigation processes have also been developed. The resilience of optical surfaces to laser damage can be significantly improved with a special chemical process that removes impurities and micro-cracks.

In addition, parameter adjustments and new processes during grinding have also been developed. Reduced grain sizes and UAG (ultrasound-assisted grinding) significantly diminish the depth of SSD. Moreover, hard and brittle materials have some elastic (ductile) behaviour at the microscopic level (< 1µm). If the engagement of the abrasive grains is kept within this range, ductile grinding similar to the type used on metallic materials can also be achieved for hard, brittle types of glass. This significantly lessens the formation of microcracks.

The second part of this series will dwell on the positions and types of LID, and also explain the most common measuring techniques used to determine the LIDT.