Story 4: From Jena into orbit - asphericon becomes part of the Copernicus mission

What was not possible before now becomes possible: In order to be able to supply high-precision optics for a satellite, asphericon developed a new polishing process with an unprecedented level of accuracy.

Targets of the Sentinel-4 mission © Airbus Defence Space

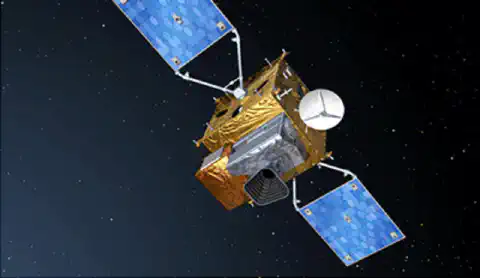

Sentinel-4-Satellit © ESA - P.Carril

When Jena-Optronik, a manufacturer of high-precision space optics and electronics, first approached us with an unusual request in 2011, the requirements for the project were far beyond what was technically possible at the time. The request: to supply special aspheres and spheres made of soft calcium fluoride materials to equip the spectrometers of the Sentinel-4 Earth observation satellite. The required error tolerance of a few nanometers in the shaping - in the case of the surface roughness values they were even in the Ångström range - presented us with challenges. But there was no reason not to give it a try.

To deliver the high-precision optics for the Earth observation satellite, we developed a new polishing process that allows extreme accuracy with deviations smaller than the millionth part of a millimeter (related to the RMS value of the surface form deviation). “Polishing these large lenses from the difficult materials to a low roughness was something we had to accomplish. We managed to do it with less than 5 angstroms and can offer this know-how to our customers in other areas, for example, for laser optics,” explains Dr. Ulrike Fuchs, who was in charge of the project at the time. Sven Kiontke remembers the process and how well the cooperation worked: “The customer request arrived shortly before Christmas and our R&D and production team delivered a working solution in the shortest possible time. Perfect teamwork, despite time pressure and the demanding end-of-year business.”

Our Ångström polishing process, with its unprecedented level of accuracy, provided the crucial building block to realize the project and ensure the required high resolution of the camera systems. This was unique at the time.

asphericon's optics for Sentinel-4: spherical and aspherical lenses with diameters from 50 mm to 80 mm, a spectral resolution from 0.12 to 0.5 nm and Ångström polish roughness values of 5 Å

According to the plan of the European Space Agency (ESA), Sentinel-4 will be orbiting our planet at an altitude of 36,000 kilometers from 2023. It will provide data on the concentration of potentially harmful aerosols, trace gases and the most important air quality parameters thanks to precise measurement technology made in Jena, made by asphericon.