Optical Assembly

Custom-fit solutions for maximum precision

Customized assembly and mounting of optical components

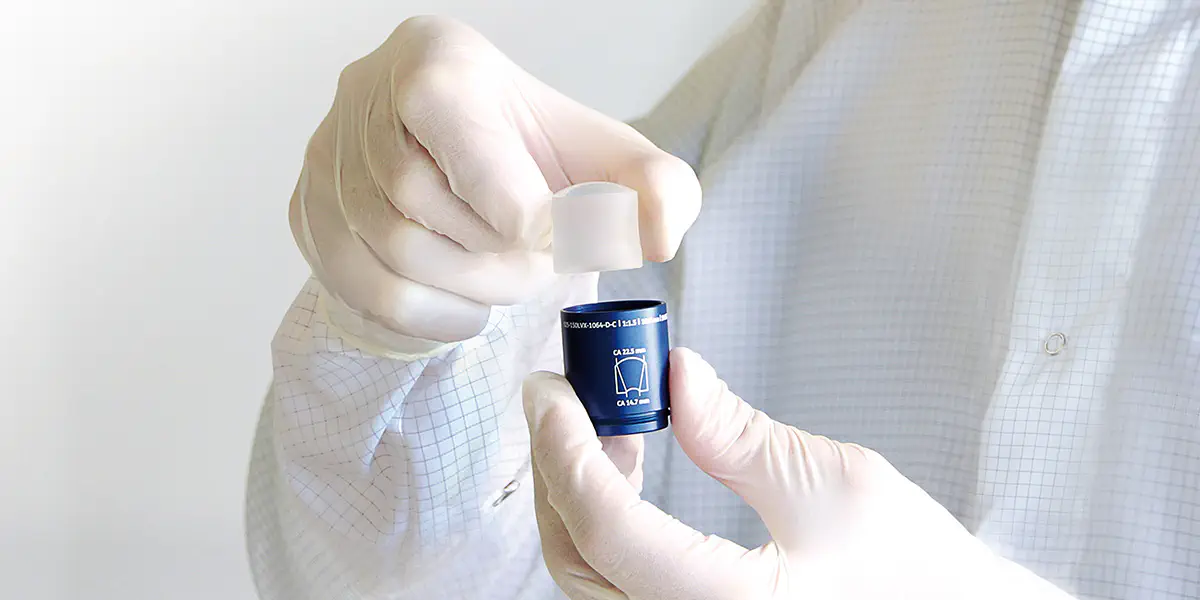

Whether standard or custom-made, asphericon develops and manufactures optical mounts that meet the highest requirements for precision, stability, and reproducibility. Advanced adjustment and manufacturing processes achieve decentering of < 5 µm, ensuring precise alignment between optics and mechanics.

The result is mounting solutions that fully exploit the performance of the optical components while reliably protecting them from environmental influences. From standardized plug-and-play solutions to fully customized mounts, asphericon offers a broad portfolio for industrial and research applications, complemented by cleanroom assembly and customized packaging options.

Plug-and-play perfection — standardized mounts

asphericon offers a well-designed standard portfolio for fast, adjustment-free use in laser and research applications.

Your advantages:

- Standardized 30 mm mounts for easy integration into optical setups

- Precise alignment to the optical and mechanical axes

- Laser-engraved lens specifications for clear, reliable identification

- Compatibility with all common systems through a range of adapters

- Available for all StockOptics Aspheres and Axicons (12.5 – 25.4 mm)

The result: ready-to-use plug-and-play solutions that combine precision with ease of use.

Customized solutions for the highest demands

When standard solutions are not sufficient, asphericon offers comprehensive manufacturing capabilities for individual optical mounts and holders.

Your advantages at a glance:

- High-precision adjustment to the mechanical axis (< 5 µm)

- Robust designs and secure storage thanks to protective caps

- Wide range of surface treatments, such as anodizing, painting, laser engraving, and nickel–phosphorus (NiP) coating

- Intelligent labeling and optimized packaging

- Cleanroom assembly according to ISO 7 or ISO 5 for sensitive systems

Housing and mount manufacturing

Mounts and housings are manufactured using advanced turning processes that ensure precise alignment between optics and mechanics. This achieves decentering of < 5 µm — a critical factor for maximum image quality.

We work with established materials such as titanium, brass, stainless steel, and aluminum alloys to ensure robustness and durability. When specific thermal or mechanical properties are required, special materials such as Invar (iron–nickel alloy), RSA or ceramics are also available. The result is robust, precisely fitted mounts that meet even the tightest tolerances and are ideally suited for demanding applications in industry and research.

Treatment of mechanical components

To ensure the longevity and functional reliability of its components, asphericon employs modern finishing and protection processes:

- Tempering and aging for stress relief and dimensional stability

- Anodizing, painting, and laser engraving for surface protection and clear identification

- Nickel-phosphorus (NiP) coating for maximum wear and corrosion resistance

Cleanroom assembly according to ISO standards

For particularly sensitive optical systems, asphericon offers assembly in cleanroom environments compliant with ISO 7 or ISO 5 standards. This ensures maximum cleanliness and consistently high quality for demanding, high-end applications.

Packaging and logistics solutions

Protection does not end with production. Well-designed packaging and logistics solutions ensure safe transport and reliable storage of your optical components:

- Packaging under cleanroom conditions (ISO 7/ISO 5)

- Standardized or customized packaging, including solutions produced using 3D printing

- Sealing under a nitrogen atmosphere for sensitive components

- Individual labeling options, such as temperature and shock sensors, QR codes, or special markings