Monolithic Germanium Freeform Optics

Reference project

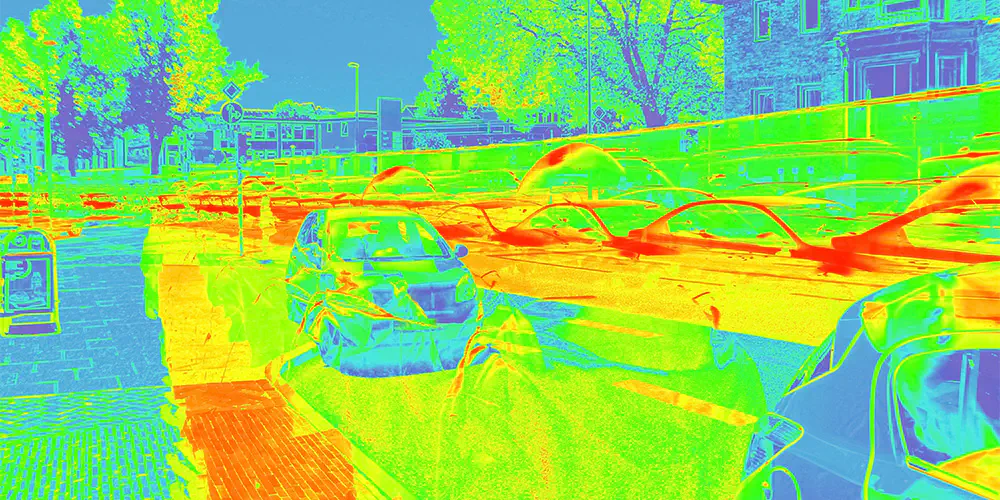

IR Optics for Assisted Driving Devices and Object Detection

Together with regional partners, companies and research institutions, asphericon has been working on the development and commercialization of innovative freeform optics and freeform optical systems since 2014 as part of the “Freeform Optics Plus (fo+)” research project. The highlight of this collaboration was the awarding of the “Forschung im Verbund” science prize by the Stifterverband der Deutschen Wissenschaft for innovative approaches to the production of freeforms in 2018.

The outcome of the project includes IR optics for an assisted driving system. asphericon developed freeforms that exceed the requirements for compact design, easy integration and high resolution in such systems. Thanks to innovative manufacturing techniques and precise engineering, the volume of the optics was reduced by 75% and an excellent image quality was achieved.

Project description

Thermographic imaging is, among numerous other sensors, an essential part of assisted driving systems, e.g. for detecting pedestrians in the driveway. In addition, to being as compact as possible, there are also requirements for easy integration of the optics into the sensor, low susceptibility and high resolution. To meet these requirements, a monolithic IR freeform element was designed within the fo+ project, under the patronage of the German Federal Ministry of Education and Research. As an essential part of this project, asphericon developed the complete technical production chain for the optical freeform system, the definition of the reference system and the design of the overall shape of the monolithic element.

Project implementation

asphericon developed and manufactured a monolithic IR element that combines three aspheres and a freeform surface, essentially folding the beam inside a mirror system (see Fig. 1). The freeform has a deviation of 25 μm from the best-fit sphere with a total sagitta of about 200 μm and compensates for the aberrations of the system. As a result, the volume of the optics has been reduced by 75% to 2.6 cm3 while maintaining excellent imaging quality.

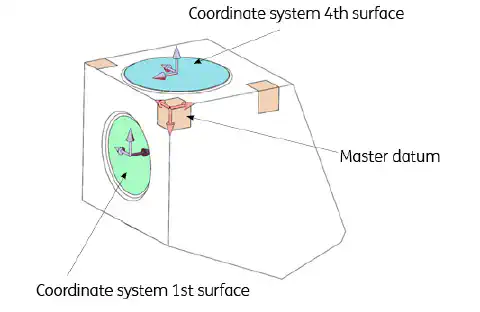

Figure 1 Layout of the monolithic system consisting of three aspheric and one freeform surface.

The most challenging part of the manufacturing process was the correct positioning of all optical surfaces in relation to each other, since tilt and misalignment directly result in a loss of image quality. Therefore, asphericon defined a set of coordinate systems and a master datum (shown in Fig. 2) for the monolith and designed certain reference areas.

Figure 2: All surface coordinate systems are referenced to a base coordinate system of the monolith, which acts as a master datum, defined according to ISO 10110.

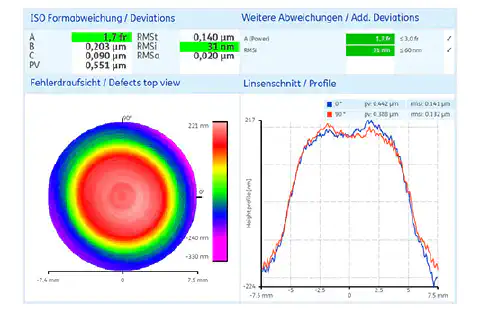

These reference surfaces facilitate the integration of the optics into the thermographic sensor. As a result, the specifications for surface form deviation and imaging capacity were clearly exceeded (see Fig. 3), e.g. with a RMSi of 31 nm.

Figure 3: Full surface measurement of surface form deviation of the freeform, showing an outstanding quality with a RMSi of 31 nm.

Since the end of the project in 2022, asphericon has continued to work in-house on the development of innovative freeform optics and systems as well as the continuous optimization of series production. Further information can be found at freeform optics.

Optics for fo+ at a glance:

- Development of methods for processing freeform surfaces on various materials (UV, VIS, IR) as well as of a germanium monolith for simplified positioning of IR optics, e.g. in thermographic systems

- Reducing the volume of the optics by 75%

- Achieving excellent image quality with RMSi of 31 nm