Freeform Optics

Powerful, compact and lightweight

Precision for demanding optical systems through freeform optical surfaces

Freeform optics enable entirely new approaches to the design of modern optical systems. Their complex, non-rotationally symmetric geometry introduces additional degrees of freedom in optical design, enabling compact, lightweight, and high-performance solutions — for example in laser applications, hyperspectral imaging and beam shaping.

asphericon is your experienced partner throughout the entire process, from design consulting and prototyping through to series production. Using state-of-the-art CNC machining, advanced metrology, and precision optical coating technologies, asphericon delivers solutions that meet the highest technical standards.

Advantages of freeform optics at a glance

Freeform optical surfaces offer unique functional and structural advantages:

- SWaP optimization: compact design with reduced size and weight (SWaP = Size, Weight, and Packaging )

- Volume reduction: folded beam paths and functional integration

- Higher performance: improved numerical aperture (NA) and larger field of view (FOV)

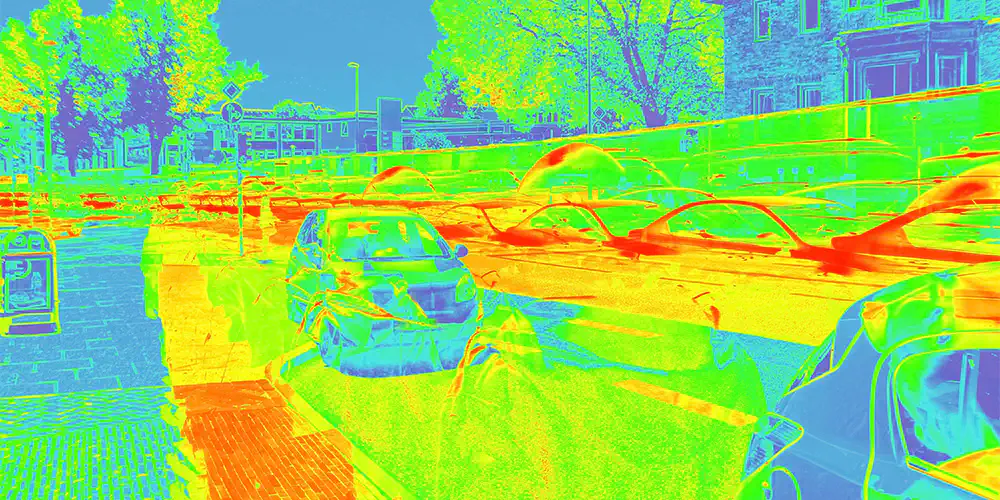

- Broad applicability: including hyperspectral imaging, IR detection, and beam shaping

- Dynamic systems: such as Alvarez optics with variable focal length

Specifications

| Standard Quality | Precision Quality | Diamond-Turning | ||

|---|---|---|---|---|

| Diameter | 8 – 300 mm | 4 – 300 mm | 1 - 300 mm | |

| Diameter Tolerance | ± 0,1 mm | ± 0,01 mm | ||

| Center Thickness | 2 - 60 mm | 2 - 60 mm | ab 0,5 mm | |

| Center Thickness Tolerance | ± 0,1 mm | ± 0,05 mm | ||

| RMS Irregularities (RMSi) | 0.75 – 0.3 µm | 0.09 µm | 0.1 µm | |

| Surface Roughness | 2.0 – 3.0 nm | 1.5 – 2.0 nm | bis zu 1 nm | |

| Full-surface Interferometric Measurement | optional | optional | optional | |

| Coating | customer-specific | customer-specific | customer-specific | |

| Materials | customer-specific (including ceramics) | customer-specific (including ceramics) | customer-specific (including ceramics) | |

| Mounting | customer-specific | customer-specific | customer-specific |

Step by step to the perfect freeform system

The development and production of complex freeform optical systems start with a precise specification — whether as an analytical equation, point cloud, or complete 3D CAD model. While relatively simple systems can still be realized using off-axis spherical or aspherical surfaces, true freeform performance is achieved through the targeted design of asymmetric geometries with multiple degrees of freedom.

This geometric flexibility opens up enormous functional possibilities, but it also places extremely high demands on design, manufacturing, and metrology. asphericon supports the entire value chain through a fully digital workflow — from design optimization and high-precision CNC machining to optical coating and comprehensive metrological verification of complete components, including positional tolerances and system-level requirements. A digitally networked manufacturing architecture ensures that every production step is documented, clearly displayed, and fully traceable at all times.

Customized optical design

Customized optical design Digital tracking of every manufacturing step

Digital tracking of every manufacturing step Unusual materials (e.g., ceramics) and extensive testing

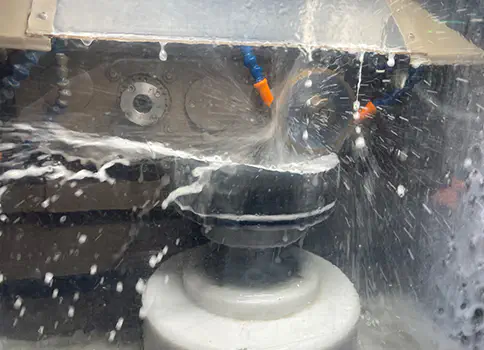

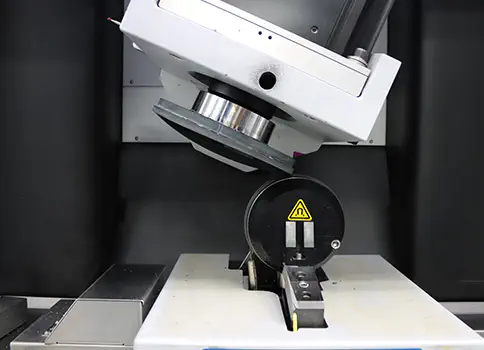

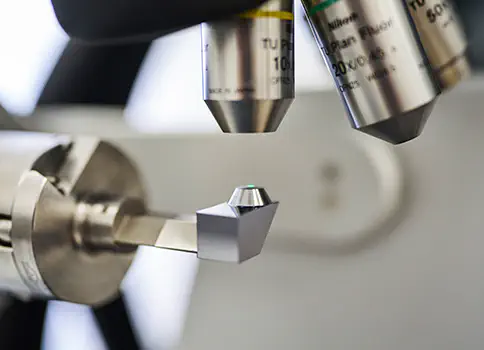

Unusual materials (e.g., ceramics) and extensive testingHigh-precision CNC machining accurately reproduces even the most complex geometries. MRF polishing (magnetorheological finishing) delivers maximum precision. State-of-the-art metrology, including advanced 3D measurement techniques, ensures reliable verification of all relevant optical parameters.

Precision CNC machining

Precision CNC machining MRF polishing for even greater precision

MRF polishing for even greater precision State-of-the-art 3D metrology

State-of-the-art 3D metrologyDuring production and before delivery, each optic undergoes standardized inspection and cleaning procedures. asphericon provides optical coatings across the entire spectral range from UV to IR, using sputter technology to achieve ultra-hard and durable coatings. Environmental tests (e.g., salt spray testing) confirm the robustness of freeform optics even under extreme conditions.

Assembly and inspection under cleanroom conditions

Assembly and inspection under cleanroom conditions High-performance coatings from UV to IR

High-performance coatings from UV to IR Environmental testing

Environmental testingSpecial expertise: monolithic (MOS) and dynamic optics

A key area of expertise at asphericon is the development and production of monolithic optical systems (MOS). These systems combine multiple optical functions (often including freeform surfaces) into a single component. The advantages include:

- reduced volume

- lower assembly effort

- significantly increased system stability

asphericon’s MOS solutions are particularly well suited to folded beam paths and complex imaging tasks. Precise adjustment specifications and integrated assembly aids enable straightforward system integration, and in some cases even adjustment-free assembly — significantly reducing costs and time. Manufactured from a single piece, monolithic optics are also exceptionally robust, making them ideal solutions for harsh environmental conditions.

Dynamic optics with Alvarez systems

asphericon is also an experienced development partner for dynamically adjustable optical systems. Alvarez optics — consisting of two freeform optical surfaces that can be shifted relative to each other — enable variable focal lengths, zoom functions— or beam correction in a compact, precise, and adjustment-free design. asphericon supports the full process from the concept phase through to series production.

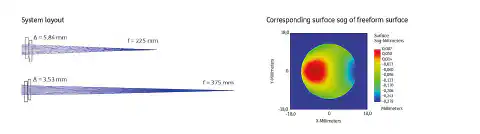

Figure 1: Dynamic change in the focal length using an Alvarez lens system.

Freeform optics — specifications, advantages and challenges

Freeform optics differ fundamentally from spherical and aspherical surfaces. Their geometry provides many degrees of freedom in optical design, enabling very high image quality along with substantial reductions in size and weight.

Unlike rotationally symmetric optics, which often introduce aberrations in off-axis configurations, true freeform surfaces allow targeted optimization of image quality, system size, and weight. In many cases, they can replace bulky mirror systems — especially in folded beam paths, such as in compact monolithic designs.

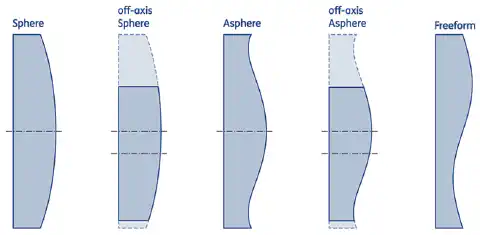

Figure 2: Evolution of lens geometries from spherical to freeform optics (increasing complexity from left to right)

Compared to conventional lens designs, freeform optics allow parameters such as the field of view (FOV), numerical aperture (NA), and wavefront quality to be maintained while simultaneously miniaturizing the design. Their production, however, is challenging because geometry definition, machining, and measurement are all highly complex. For further insights into design principles, manufacturing processes, and reference projects, visit our blog.

Are you planning a project with freeform optics?

Our team of experts will be delighted to support you from the initial idea to the finished component. Draw on decades of experience, advanced manufacturing technologies, and the flexibility of an internationally active optics manufacturer.

Reference project

Your request