Stable Wavefront

Special features of a|TopShape – Part 1

Do you know how our digital production ensures a working distance of more than 1,5m for our TopShape?

Producing an alternative shape is only half of the trick in beam shaping. Maintaining the shape over a long working distance is at least as important.

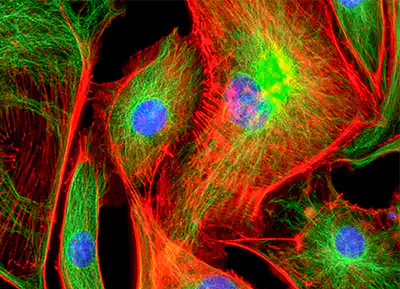

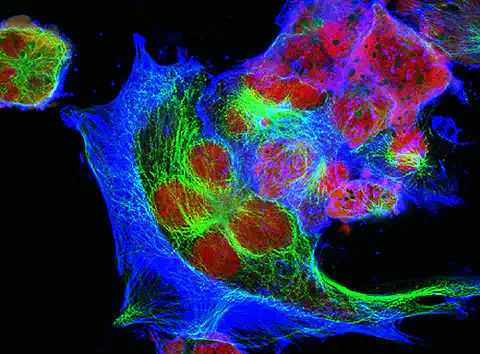

Especially in Total Internal Reflection Fluorescence (TIRF) microscopy, where the quality and uniformity of illumination are of utmost importance. Here, beam-shaping tools have become increasingly popular, e.g., transforming an uneven Gaussian beam profile into a top hat profile that offers a more uniform illumination.

However, the optical path in TIRF microscopy setups is often quite long, requiring the beam shaping to maintain a flat wavefront over a long distance. This might become a challenge.

An important reason for wavefront distortions are surface imperfections on the optical elements. When passing through an optical element, such imperfections can lead to optical aberrations or scatter light, distorting the image quality and the wavefront. So, beam shaping tools for TIRF microscopy need an optimal surface quality.

At this point, the benefits of our digital production process come into play. At asphericon, we track a wide range of parameters throughout production, from the single lens data to the precise operations on our manufacturing lines. The comprehensive data we collect during production is not just for record-keeping. We leverage this information to gain insights into how each production parameter affects the optical properties of our components. This data-driven approach is key to our ability to produce aspheric optics that consistently meet our high standards for surface quality and allow us to minimize wavefront distortions of our lenses.

The TopShape beam shaper exemplifies this approach. It transforms a Gaussian beam into a flat-top profile, preserving the wavefront’s integrity. As a result, the laser beam can still be focused tightly and additionally facilitates uniform illumination across a larger field of view. This simplifies the imaging process by eliminating the need to merge multiple fluorescence images.

For researchers and professionals looking to enhance their TIRF illumination with a flat-top beam profile and to discover the advantages of our TopShape beam shaper, we invite you to reach out. Delve into the specifics on our product page or engage with our team for a deeper insight into how we can enhance your TIRF applications.