Beam shaper for laser material processing

Reference project

Improving laser material processing with beam shaping from asphericon

Although Gaussian beam profiles can be used to generate small structure sizes by direct material ablation, they show weaknesses in terms of ablation depth and quality. Due to their characteristic shape of the profile, the intensity decreases at the edges of the beam and causes inhomogeneous ablations. In cooperation with Otto Schott Institute for Materials Research in Jena, asphericon analyzed different focused intensity distributions (e.g. Top-Hat, Donut) regarding their suitability for material processing with femtosecond lasers.

Project Details

Beam shaping is especially suitable for laser material processing, such as cutting, welding and marking in the field of micromachining. Although Gaussian intensity distributions can be used to realize small structure sizes by direct material removal, there are weaknesses regarding removal depth and quality. The intensity decreases at the edges of the beam and thus causes inhomogeneous ablation. In addition to optimizing the laser and processing parameters, the adaptation of the focal intensity distribution offers great potential for high-precision results. In cooperation with Otto Schott Institute of Materials Research (OSIM) in Jena, asphericon analyzed various tailored intensity distributions (e.g. Top-Hat, Donut) regarding their suitability for femtosecond laser material processing on micro- and nanoscales such as cutting and marking.

Project Realization

To obtain different focused intensity distributions (especially Top-Hat) asphericon’s a|AiryShape was used. It first converts a collimated Gaussian beam into a collimated Airy- or Bessel-sinc shaped intensity profile by means of a phase plate. Second, a focusing lens performs a Fourier transformation on the input intensity function and the corresponding Fourier counterpart occurs in its focal plane. The a|AiryShape allows several intensity distributions (e.g. Top-Hat, Donut) to be generated in different working planes with one set-up, while convincing by its extremely short overall length (17.3 mm).

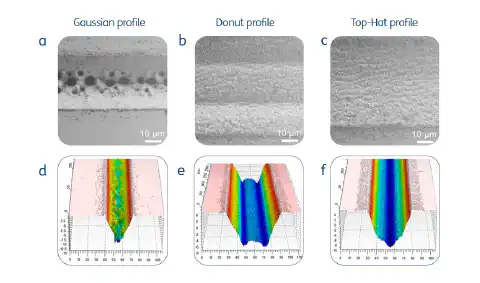

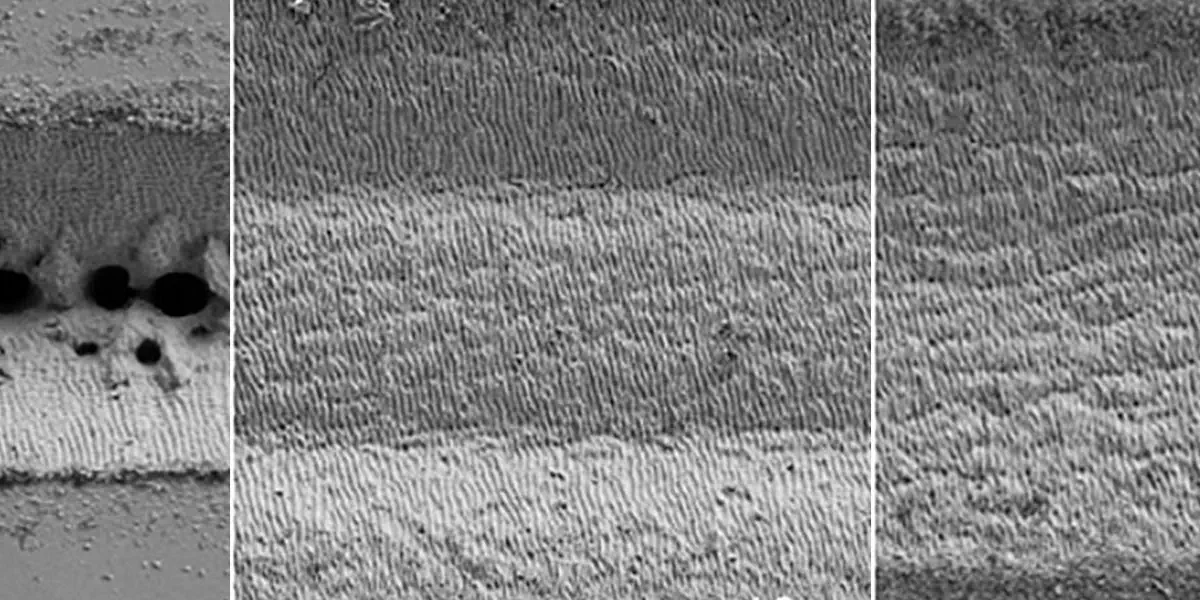

Figure: Comparison between Gaussian, Donut and Top-Hat profile. a – c = scanning electron microscope (SEM) micrographs of channel-like structures of pulses fabricated by fs-laser ablation (scanning single line v=0.1 m/s, 1000 iterations, Eim=11.3 µJ as function of the number of overscans using different focal intensity distributions); d - f: white light interference microscopy (WLIM) micrographs, 3D geometry of corresponding channels obtained from ten overscans

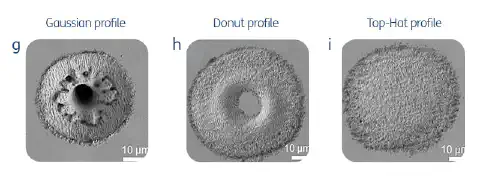

Figures a - c show the line scans performed with different beam profiles. Compared to the (inhomogeneous) Gaussian profile (Fig. a/d), beam profiles generated with a|AiryShape (b/e: Donut; c/f: Top-Hat) show a very homogeneous ablation. The beam shaping device is suitable for working with a scanner and F-Theta lens as commonly used for material processing. The following SEM micrographs show the results of single spots on stainless steel as a function of the fs laser pulse (N=200). Donut and Top-Hat show lower ablation depths (range 5-10 µm) due to the distribution of the pulse energy over a larger area. This allows, for example, a more uniform material ablation.

Figure: Results from single spots on stainless steel. Donut and Top-Hat profile produce lower ablation depths due to pulse energy distribution over a larger area.

Optics for laser material processing at a glance

- Compact beam shaper for generating different focused beam profiles (Top-Hat, Donut, Beam waist) in various working planes

- Enlargement of channel widths and smaller ablation depths due to a more homogeneous distribution of the pulse energy on a larger area

Learn more about the principle of our beam shaper a|AiryShape at: asphericon.com/en/solutions/products/beamtuning/beam-shaping/