Story 8: „Shape it ‘til you make it“

A construction kit for laser applications or a Lego set for physicists: Creating the BeamTuning series and product development at asphericon

a|BeamBox including certificate

On opening the a|BeamBox case, the optical elements with their elegant, blue anodized mounts are neatly arranged in place. A manual is enclosed explaining how to use the items. When asphericon’s BeamTuning series for shaping and expanding laser beams was launched, it was the first of its kind – there was nothing like it on the market. asphericon created the first mounted optics with the plug-and-play principle, and in doing so revolutionized the view of aspherical lenses. “The quality of our aspheres is simply extremely high. No one in the industry had the nerve to make anything like it before. It’s a really cool product!” declared Dr. Ulrike Fuchs, Head of Product Development, proudly.

Asking how the series came about raises quite a few smiles among the staff! It all started with a theoretical consideration of monolithic telescopes in 2012. “While playing around with a few ideas with a client, we sketched out by hand all the ways in which different lenses can be positioned: lined up in a row, arranged in cascades, and so on.” This resulted in completely new solutions for a wide variety of applications in for instance the lab, metrology, and laser materials processing. Every combination suddenly became feasible and conceivable.

The sketches were also the basis for the BeamTuning poster

The idea of turning this into a product series of its own was prompted by CEO Sven Kiontke, who encouraged the team to keep working on the project. As Dr. Fuchs recalled: “That was very exciting. Because until then, we hadn’t really produced or developed much like it. It was also the first time we’d designed mounted optics.”

No sooner said than done. Mind you, the time frame for the development of the new products was very ambitious. asphericon wanted to showcase them at a trade show just a few months after the idea had been born and taken shape. Since the company didn’t yet have its own optics laboratory, a business partner’s lab in Paris was booked for the characterization of the lenses.

The BeamTuning range is now well and truly established and very popular. The team at asphericon acquired plenty of expertise from the development process, solving questions like: How do you anodize items in the colour of your choice? How can the mounts be produced so that the optics can be seamlessly inserted? How can manufacturing challenges already be addressed and solved during the design and tolerancing of an optic?

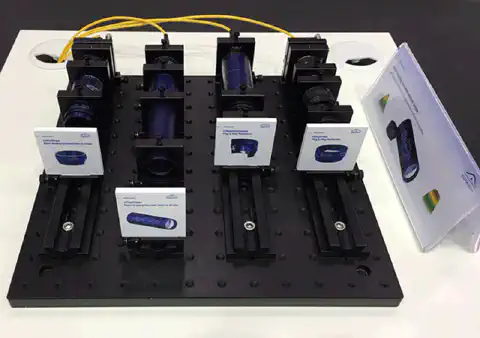

BeamTuning booth set-up

In addition to looking extremely elegant, the mounts used for the BeamTuning series have such a high specification that money couldn’t buy them at the time. Since asphericon still produces the mounts in-house, it can directly influence their quality. A whole periphery has since been set up, benefiting other products and giving real added value to the development and shaping of other product ideas at the company.

The BeamTuning series is completed by supplementary features, such as the specially developed BeamTuning app, a user manual, a poster showing how the individual components can be combined, and videos, all demonstrating that at asphericon, practical added value for users is at the forefront of our considerations.