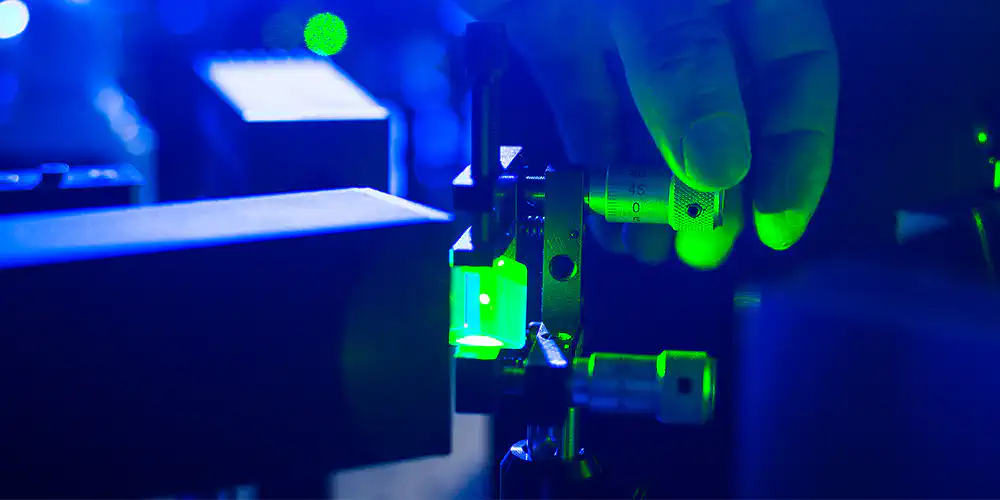

You can’t get any smaller and more precise

ultra-short pulse lasers and their progress in science and industry

Content

Laser pulses in a trillionth of a second for cutting, welding and structuring

Ultra-short pulse laser (USP laser for short) is the generic term for all laser sources that generate pulsed laser beams in the picosecond or femtosecond range. These very short laser pulses ranging from a trillionth to a quadrillionth of a second (≙ 10-12 – 10-15 sec; for comparison: the blink of a human eye lasts about 300 – 400 milliseconds) are mainly used in materials processing, life sciences and research. Due to the extremely short period of time over which the energy of the emitted radiation is concentrated, USP lasers achieve extremely high peak pulse powers into the megawatt range, and even into the gigawatt range with additional spatial focusing. These high intensities make it possible to ablate almost any material, regardless of hardness, evaporation temperature and absorption range. This is based on non-linear effects resulting from the interaction of light and matter.

Differentiation from other lasers

If a material ablation process, such as laser welding or surface structuring, makes use of a USP laser, the material is ablated due to the very high temperatures/short interaction time resulting from the direct phase transition from the solid to the gaseous state. When other types of lasers are used, the heating of the material by the laser beam first causes it to melt and only then to vaporize. That’s why (material) processing using ultra-short pulse lasers is also referred to as “cold processing”. Ideally, the applied energy is completely emitted via the ablated particles. Except for a microscale interaction zone, the material to be processed remains completely cold. Alongside their very high degree of precision, another advantage of USP lasers is that even challenging materials (e.g., delicate composites, polymers, and even human tissue) are easy to process. A wide variety of shapes can be structured, drilled and cut to within the micrometer range.

Thanks to the above-mentioned special characteristics, the use of ultra-short pulse lasers opens up new possibilities for processing materials and surfaces that are not feasible with conventional (laser) tools.

Materials processing by USP laser in industry

As already mentioned, the use of USP lasers minimizes the thermal load, thus enabling the processing of very thin (µm range) or (heat) sensitive materials. For example, glass can be cut cleanly and without any cracks at the edges using USP lasers. This also makes USP-based processes attractive for the production of displays (e.g. for smartphones). The ultra-short yet intense energy input ensures spot vaporization and thus precise cutting edges and structures, regardless of the material thickness, e.g. even with ceramics and metals. Spot processing, such as drilling, is possible to within the µm range and is used, among other things, in photovoltaics manufacturing.

USP lasers can be used not only for laser cutting, but also for laser welding. This thermal process can replace adhesives and ensures that even disparate materials are firmly bonded together. Ultra-short pulse lasers can also be used for surface structuring/roughening of material surfaces prior to welding. Surface structuring by means of USP laser can even replace coating in some applications.

Thanks to their pinpoint precision, ultra-short pulse lasers are increasingly used in the semiconductor industry, such as for wafer cutting, where they are used to drill holes with micrometer precision and to connect the very fine PCB tracks. Silicon wafers can be ablated without causing damage or cracks.

Alongside the high structural quality and low surface damage described above, laser marking/inscription also leverages the chemical resistance involved in USP processing. Lasers are already a proven tool for the creation of marking, e.g. on components or products. USP lasers enable durable marking without burrs to within the single-digit micrometer range.

Ultra-short pulse lasers in medicine and science

The benefits of precise cutting edges and clean processing can also be applied to the medical sector. Ceramics used in medical technology, such as aluminum oxide or zinc oxide, which are increasingly used thanks to their mechanical, thermal, electrical and chemical properties, can be precisely cut and processed without cracks using USP lasers. Micro-cuts generated by ultra-short pulse lasers are essential for the production of stents, among other things.

In medicine, ultra-short pulse lasers can not only be used to process materials, but also to treat the human body. In the field of ophthalmology, for example, they are used to treat cataracts and facilitate high-precision, low-damage incisions in the eye. USP lasers are used to pulverize the ink particles in the skin as part of tattoo removal. In the process, tattoos are removed without damaging the surrounding tissue.

In science, USP lasers enable the observation, detection and modification of ultrafast processes and are used, for example, in various spectroscopic and microscopic applications. Examples are laser scanning microscopy (e.g. multiphoton microscopy), ultrafast spectroscopy (includes all spectroscopic measurement methods with temporal resolution in the femtosecond range) or optical coherence tomography (medical diagnostic method using light with low coherence length to measure scattering distances).

From micro to macro processing – Future development of USP lasers

USP lasers have long been used in materials processing, medicine and science, due to their impressive advantages, such as::

- Strong localization of the energy input (at the point of impact/nanoscale interaction zone)

- Prevention of melting deposits

- Targeted use of non-linear absorption mechanisms

- Very high degree of precision and structural quality

- Processing of very thin materials to within the µm range

Industry, too, is increasingly appreciating the advantages of these lasers. Attempts to deploy USP lasers within series production have already been tested and further developed in the last few years. Higher laser powers will take this technology to the next level. The first ultra-short pulse lasers that generate a power of several hundred watts and even more than one kilowatt are already available on the market and facilitate processing methods in the macro range. Higher power levels will even make it possible to machine ultra-hard materials in the medium term.