Comparison of tactile measurement methods

Production accompanying measurement of aspheres

Content

Independent of the application, whether in satellite optics, video lenses or endoscopes – aspheres have already become indispensable in a wide range of highly versatile technical fields of application. Regardless of the system’s size, they all have to meet one requirement: to be precise. To meet quality requirements, continued development of aspheric production and the trend towards miniaturization demand for faster and more accurate measuring methods. Measurement of the complex surfaces of aspheres is still challenging. Different measuring methods are used depending on measuring task and speed as well as surface structure. Among others, a distinction is made between non-contact and tactile measurement. The basic principle of measuring aspheric components during production based on tactile measuring methods is presented in the following.

Why do we need measurement technology?

Measurement technology plays a significant role in the production of precision optics. asphericon manufactures aspheric optics by means of CNC-controlled technologies from almost all available glass types, but also from plastics, metal and crystals (for example, CaF2, germanium, silicon). Accurate knowledge of shape and surface form deviation of the lens is necessary in each processing step to optimize the production process. With a growing demand on optics (not only for asphericon), there is also an increasing demand for production-oriented measurement technology.

Measurement tasks

Within the process chain, the measurement tasks differ as well as the measuring technology used. Measurement tasks range from the incoming goods inspection of the raw material, the determination of the lens shape between the individual work steps and the complete measurement of the finished optics for the final inspection. Measurements can be made of e.g.:

- shape of the lens,

- surface form deviation,

- slope tolerance,

- central thick and

- roughness.

Measurement of surface shape deviation using the example of grinding

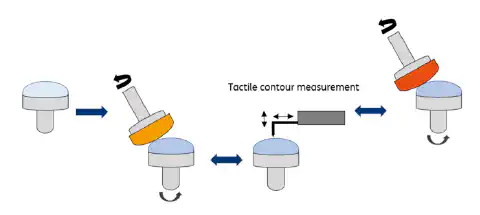

The surface geometry of an asphere deviates from a sphere, but it is still rotationally symmetric. Through the rotation of the lens during machining (Fig.1), grinding tools leave rotationally symmetric structures on unfinished lenses. For the grinding process, it usually is sufficient in sense of the measuring technique to monitor the surface contour to optimize the next working step. The advantage of this simple measurement is, among other things, a short measuring time, which contributes to the optimization of the entire processing time.

Fig. 1: Integration of tactile measurements within the grinding process

Tactile measurement methods in detail

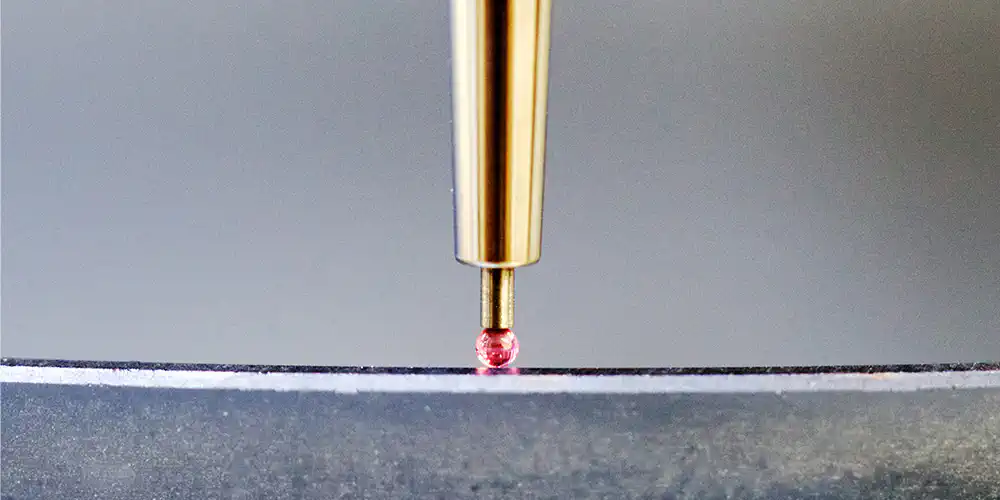

In addition to measurement tasks and process steps, as already mentioned, a distinction is made between different measurement methods. In the following, we will only discuss the tactile measurement methods by means of an exemplary presentation of various devices. This type of measurement technique is based on scanning of object surfaces, for example with ruby contact points.

Profilometer – a tactile classic

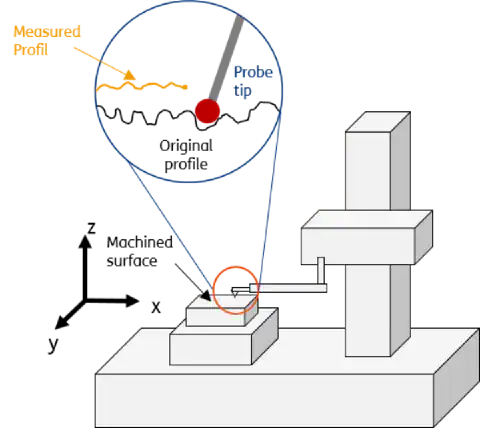

The simplest way to determine the shape of a rotationally symmetric object is to determine the surface contour. A so-called profilometer (Fig. 2) is used for this purpose. With aid of a ruby tip, which probes the measuring object in a straight line across the zenit and records the deflection of the contact point in z-direction perpendicular to its track.

Fig. 2: Scheme of a profilometer

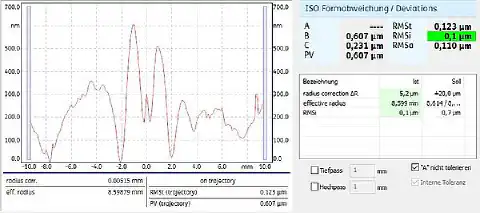

Fig. 3 shows a sample protocol of a tactile measurement. To determine this deflection, a constant measuring force is required, pressing the probe onto the lens as well a stiff probe system. Profilometers are used between two steps of the grinding process, since possible damage caused by the ruby tip can be removed in further manufacturing steps.

Fig. 3: Exemplary measurement curve of a profilometer (MarSurf LD 120)

3D coordinate measuring machine – higher complexity

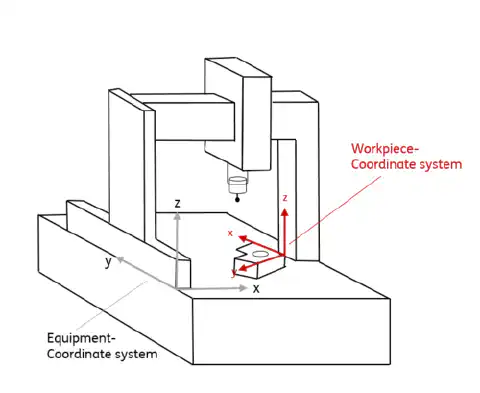

A more complex form of tactile measuring devices are 3D coordinate measuring systems (Fig. 4). These can also be used for measuring aspheres. The measuring object is traced with a probe tip whose position is determined via 3 measuring axes in Cartesian coordinates. The measurement of rotationally symmetric test objects done with a form tester uses cylinder coordinates, therefore the form tester is equipped with a highly precise axis of rotation, the so-called C-axis.

Fig. 4: Scheme of a 3D coordinate measuring system

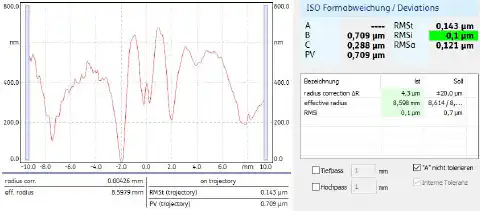

Fig 5. shows an exemplary measuring curve of a form tester MarForm MFU 200 Aspheric 3D. After initializing the measurement, to determine the zenith of the measuring object, a straight measurement is performed along the largest radius. This measurement is executed in tracking mode. Therefore, a constant pressure is used to guide the tip along the profile and record the change of the z coordinate.

Besides profile measurements, form tester can be used for diverse applications such as determination of roundness, cylindricity and run.

Fig. 5: Exemplary measurement curve of a form tester (MarForm MFU 200 Aspheric 3D)

Limits of tactile measurement

The use of tactile measuring methods within the polishing process allows a relatively rapid knowledge of the surface contour of lenses. On the other hand, a decisive disadvantage is the possible damage of the lens surface by the probe. Any damage that may occur, however, could possibly be removed in later work steps. The resolution capability depends directly on the radius of the probe tip, which acts as a low-pass filter. Structures which are significantly smaller than the probe tip cannot be detected correctly (see detailed view in Fig. 2). Highly curved lenses can also lead to limitations of the measuring accuracy due to the steep slope.

If the advantages of tactile metrology methods are not sufficient, it is worth looking at optical measuring devices. Regardless of what should be measured, measuring task and measuring instrument have to be coordinated well in each case. The selection of the measuring method, tactile or optical, is therefore never either one or the other. The different procedures can and should be used complementary. We are going to discuss optical measurement methods with their advantages and disadvantages in a separate article.

Information on tactile measurement can be also found in a Whitepaper.