Cleaning optics properly

A guide to handling and cleaning optics

Content

The basic requirement for a long lifespan and the preservation of quality of precision optics is the high level of care in handling and cleaning. Depending on the material, the coating as well as the degree and type of contamination, various things must be considered. In the following, we would like to share our experience in cleaning optical components with you and have compiled tips for the correct handling of sensitive optical surfaces.

Cleaning optics – Why?

Contamination, such as dust and water, can not only damage the optics but also affect their function. Particles on the lens surface cause scattered light as well as, in combination with high laser power, thermal effects up to the destruction of the lens.

Storage and transport

Precision optics are usually supplied and stored in a pergamine bag or optical tissues to protect them from dust and other contaminants. Packed in this way, the lenses are placed in a padded carton or blister to protect them from mechanical stress.

The correct handling

Always unpack sensitive lenses in a low-dust, temperature-stabilized room, such as a laminar flow. First let the lenses be tempered, as these might react very sensitively to temperature fluctuations, depending on the glass used. Please note that this process may take some time depending on the size of the lenses.

Always use clean, powder-free gloves when handling optical components. Never touch the optically effective surfaces and use tweezers if necessary to grip small lenses.

Before cleaning

Before cleaning a lens, you should ask yourself some questions to determine the correct procedure. Pay particular attention to the following aspects:

- Sensitivity of the material

- Resistance of the coating

- Type of contamination

- Degree of contamination

- Number of lenses to be cleaned

Depending on application and wavelength, lenses are manufactured from different types of glass. These differ not only in the optical effect, but also in chemical resistance and durability. First, check which material the optic was made of and whether this requires special precautions, for example regarding the cleaning agents to be used. Make sure that the coating is suitable for mechanical cleaning before cleaning the lens.

Another aspect is the optical coating. Metallic mirrors, for example, are very sensitive to mechanical stress. Mechanical cleaning may not be possible under certain circumstances, or only with the utmost care.

In general, unnecessary cleaning steps should be avoided to prevent accidental damage to the high-quality optical surface. First, it is advisable to examine the lens carefully using a high-intensity lamp. If the light is dropped flat on the lens surface, impurities such as dust particles are easily visible. The type and extent of contamination gives an indication of the cleaning technique to be used.

Cleaning techniques

After estimating the surface and the degree of soiling, the actual cleaning process begins. In the following we present some techniques.

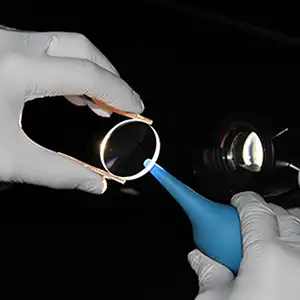

“Compressed air” – Even with careful handling of a lens, contamination by dust particles can hardly be avoided. These should first be removed with compressed air, e.g. by means of a bellows or from the can. The lens is then checked again to see whether the cleaning has already been successful.

Figure 1: Generation of compressed air by means of a bellows.

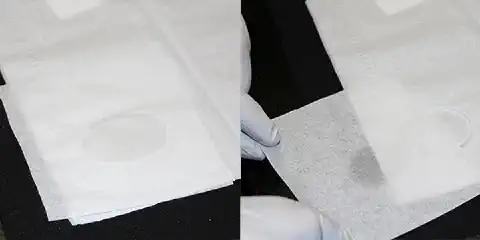

“Drop and Drag” – If an unmounted lens has only slight impurities, this method is used. It requires lens tissues, e.g. Kimtech Science Precision Wipes or Texwipe MiracleWipe, and a glass-cleaning solvent. Depending on the chemical resistance of the lens and the coating, this solvent consists of acetone or a mixture of acetone and methanol. The addition of methanol slows down the evaporation of the solvent and thus increases the cleaning effect.

When dropping and dragging the lens, it is placed on a clean and dust-free surface, for example on a fresh optical cleaning tissue. A second one is placed on the lens and moistened with a few drops of cleaning solution. Pull the tissue over the lens until it is dry. Repeat this procedure until the dirt is completely removed. Always use a clean, fresh cleaning tissue.

Figure 2: Sub-steps of drop (left) and drag (right).

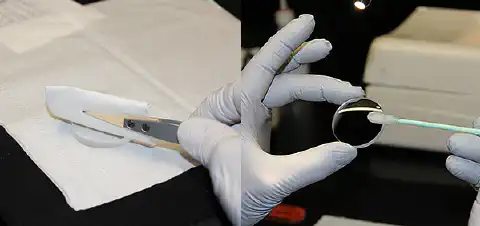

“Brush technique”– Fold an optical tissue in such a way that the fold covers the entire lens surface. Be careful not to touch the tissue on the fold. Grasp it with a pair of tweezers parallel to the fold and soak it in cleaning solvent. Avoid soaking the cloth too much. If necessary, shake off any excess cleaning solvent. Grip the lens at the edge of the cylinder and press the fold straight over the lens surface. The use of special cleaning swabs, such as Texwipe TX 761 and TX 714A, is particularly suitable for small optics.

Figure 3: Brush technique with the help of a cloth (left) and alternatively with a cleaning swab (right).

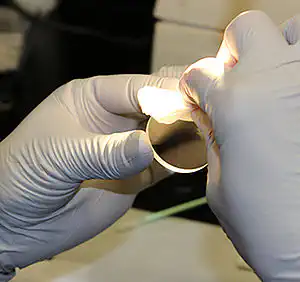

“Wiping technique”– This is used if the techniques mentioned above have not been successful. Fold the cleaning tissue as described in the brush technique and soak it with cleaning solvent. Hold the tissue between your fingers and slowly move the fold over the lens surface with moderate pressure.

Figure 4: Evenly carefully wiping with the cleaning cloth.

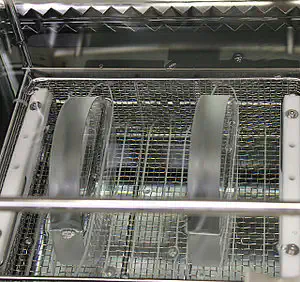

“Immersion” – Sensitive optics that do not allow mechanical cleaning are placed in a cleaning solvent. A subsequent rinsing with fresh solution and drying with compressed air prevents residues on the lens surface. An alternative is the use of an ultrasonic bath, which is also suitable for cleaning larger series or very heavy soiling.

Figure 5: Cleaning in an ultrasonic bath.

After cleaning

After cleaning, a lens should be installed directly in the setup or should be protected against new contamination with the help of a pergamine bag. In general, improper cleaning always involves the risk of damaging the lens surface and causing effects such as scattered light or absorption. Effective protection against contamination is essential for extending the service life of optics. If a lens is not in use, the risk of contamination and damage should be minimized through safe packaging.