The democratization of light

Revolutionizing laser technology

内容

Laser technology is on the cusp of a transformation: the democratization of light. What was once a tool for specialists is becoming increasingly accessible to a broader user base. Ease of use, power and adaptability are opening up the possibility of adapting light to individual needs and using it in a variety of ways. In this blog post, we will show how you can get more out of your laser applications by using intelligent optical systems.

The evolution of laser technology

Laser technology has come a long way since its discovery. From a historical perspective, today’s advances in photonics can be compared to the introduction of the electric motor in metalworking over 100 years ago. Innovations in laser technology have fundamentally changed the way we use optical systems: From a niche industry, laser technology has become an integral part of a wide range of applications.

Democratization of light

Democratization refers to developments that enable broader participation and access to resources. In laser technology, this means that even non-specialists should be able to shape and use light according to their needs. This is made possible by adaptable and powerful solutions: easy-to-use mounting systems, durable optical components and coverage of a broad wavelength spectrum.

Applications

In order to make light accessible to as many people as possible, optical systems must provide solutions that can also be used without expertise in physics or optical design. Key aspects for these products are

- quick and easy to use,

- good compatibility with existing optical and laser systems and

- high power for excellent performance.

Optical systems, such as beam expanders and beam shapers, allow the intensity distribution of a laser beam to be adjusted for applications such as

- precise cutting edges in laser cutting,

- clean welds in laser welding and

- predictable material removal precision in surface structuring.

Let’s take a closer look at these applications below.

Laser cutting

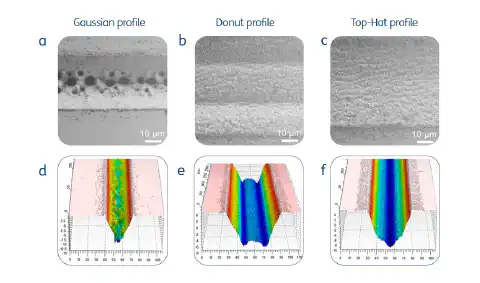

Laser cutting is one of the most effective thermal cutting processes in industrial manufacturing. Whether it is metal, wood, glass or plastic - the high energy concentration of the laser enables fast and precise cutting with clean cutting edges. In the past, Gaussian beam profiles were often used for this type of material removal. However, these have weaknesses in terms of ablation depth and quality. Due to the characteristic shape, the intensity decreases towards the edge of the beam, which does not hit the material uniformly. The result: unclean cutting edges (see Fig. 1a) accompanied by material loss and/or longer processing times due to rework.

Figure 1: Different beam profiles on stainless steel. a/d generated with a Gaussian beam, b/e and e/c with the a|AiryShape from asphericon. The profiles produced with the beam shaper show a much more homogeneous removal rate.

Figure 1 shows different beam profiles on stainless steel produced with a Gaussian (a and d), a Donut (b and e) and a Top-Hat (c and f) profile. The Top-Hat beam shaper a|AiryShape significantly improves the homogeneity and precision of the material removal compared to the Gaussian profile. Uniform ablation depths (in the range of 5-10 µm in the example) produce clean cutting edges (see Fig. 1 b and c). Due to its modular design, the product can be easily screwed onto other optical elements. No manual realignment of the beam path is required.

Laser welding

Another precise method for joining materials such as metals or plastics is laser welding. The laser heats the workpiece to melting temperature, allowing for flexible weld guidance. Traditionally, Gaussian beam profiles have also been used for laser welding. However, the uneven shape of the profile results in inhomogeneous welds.

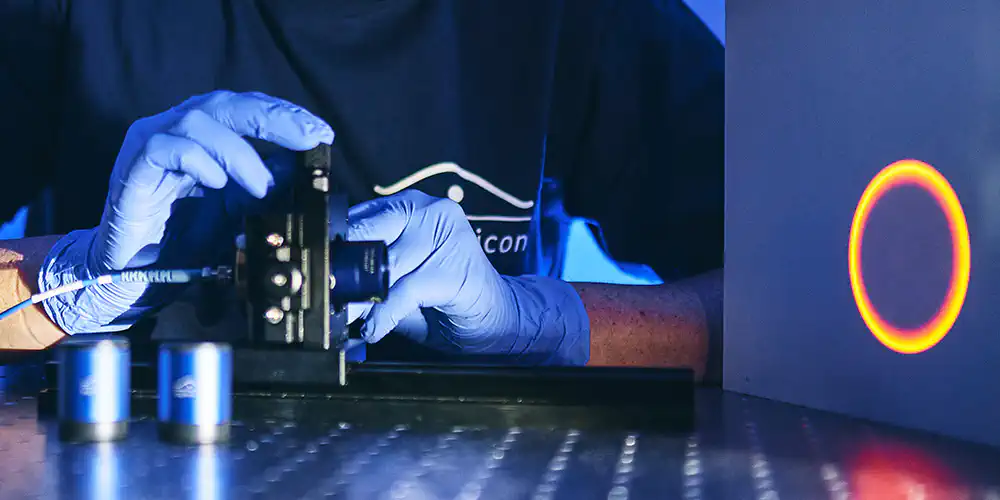

The integration of beam expanders and beam shapers can improve process stability and reduce spatter formation, resulting in gas-tight welds (see Fig. 3). Components from asphericon, such as the a|BeamExpander and a|AiryShape, can be easily integrated into existing setups thanks to the metric fine thread and ensure flexible use from 355 nm to 1600 nm thanks to a broad wavelength spectrum.

Figure 2: Seam welded by Gaussian profile with pores (top), pore-free Top-Hat profile created with an a|AiryShape (bottom).

Surface structuring

Laser surface structuring is used to create specific structures on materials such as plastics and metals, e.g. to optimize roughness values, which can play a role in adhesion and bonding. The process enables precise material removal and can be used flexibly in both single-piece and mass production. Applications range from tear-off aids on packaging to the removal of special films to optimize workpiece surfaces.

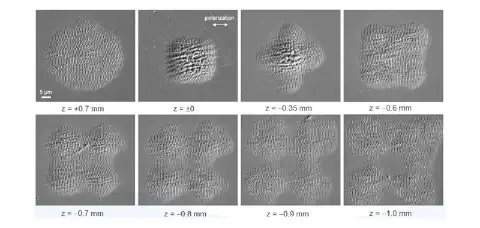

Refractive beam shapers can be used to create different round and square intensity distributions in the focus of the laser beam. This adaptivity optimizes processing time and process control. The beam shaper a|SqAiryShape used for the results shown in Figure 4 has been successfully tested to generate custom square intensity profiles. The system offers flexibility in the structuring process and allows the generation of different surface structures by varying the beam profile and the working distance to the sample surface. This beam shaper from asphericon is also highly adaptive, can be easily integrated into existing laser setups and used over a wide wavelength range.

Figure 3: SEM images of stainless steel samples after irradiation with linearly polarized fs single pulses at constant single pulse energy. a|SqAiryShape allows high flexibility in generating different square profiles by varying the working distance.

Solutions from asphericon

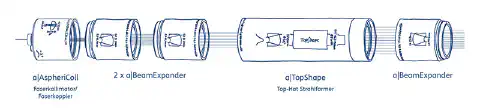

With the BeamTuning series, asphericon offers a complete product range that supports the use of lasers with user-friendly, customizable and powerful (laser) solutions. The components are easy to integrate, generate an absolutely uniform and diffraction-limited laser beam and cover a broad wavelength spectrum. As a result, complex laser technologies are greatly simplified without sacrificing power and performance, providing customized optical solutions for a wide range of applications.

Figure 4: Illustration of an exemplary beam shaping system consisting of the fiber coupler a|AspheriColl, a|BeamExpanders and the beam shaper a|TopShape.

The future of laser technology

Optical systems that enable effortless optimization of the laser beam are shaping the future of laser technology. Products that are easy to integrate, adaptable and powerful will make laser technology accessible to a wider range of users. The application examples presented here show how these principles are already being put into practice today and how they are contributing to the further development of laser technology.

Want to learn more about how you can make your laser application fit for the future? Contact our team - together we will develop ideas for your problem! You can also read the full article about the democratization of light in LASER Magazin.